Laser Welding Basics – Part 1

7 Minute Read

This article will run over multiple issues of Bench Magazine. I plan to start with the basics of welding and write about the characteristics of the beam and how we use those characteristics to weld. It is important to understand how the beam is focused. Equally important is how the viewing system is focused

Laser Welding Basics: Beam Characteristics

in relation to the focus of the beam. I will have specific examples ofjewelry related jobs that demonstrate the energy characteristics of the beam, as well as techniques and technologies (some that are rather new), that help overcome challenges that we, as jewelers, have faced over the past 10 years of laser welding.

When learning laser welding the jeweler should under- stand some basic principles of welding vs. the soldering technique most jewelers are familiar with. Anyone who has an understanding of welding principles need only learn how the lasers adjustable energy characteristics can be used to accomplish welding, and then gain a small amount of eye/hand coordination to work through magnification, using the characteristics of the beam, with some simple techniques to accomplish welding. Welding is different from soldering. Solder melts at a lower temperature and flows into a seam within metal of a different alloy content that is not molten during the soldering process. An excel- lent article on soldering principles, is in Bench Magazine: Winter 2003, Volume 2, Issue 3 titled: The Secret Life of Solder, by: William Pellegrini.

Welding is a different process from soldering mainly because when welding, the material being welded is also being melted. When melting the base material during welding it is important to penetrate into the seam with the correct energy and energy distribution to join the two pieces together in a way that produces an adequately joined area. The lasers that are being used for welding in our industry have similar adjustable features that control various aspects of total laser energy and the way that energy is delivered.

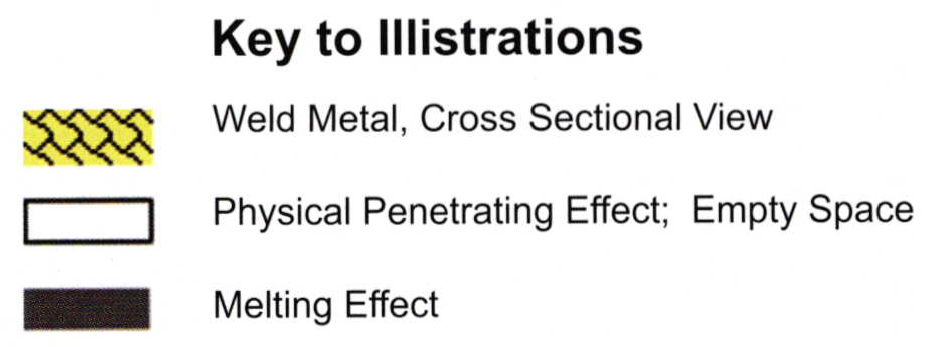

The first thing that the laser must accomplish is physical penetration into the welding seam. The laser beam has to join two pieces of metal together. This may require various characteristics of energy. For example, a 3mm platinum ring shank would require different energy than an 18k yellow gold earring post. The delivery of the beam into a welding seam is called penetration. Penetration is gained by control- ling the physical force of the laser beam that most lasers on the market control through a variable parameter called voltage. This parameter is usually expressed as voltage as well. Voltage controls the physical force of photons (matter) in the light beam. Figure 1 shows examples of weld spot cross sections using various voltage settings. The figures are not to scale, and the listed parameters are not exact; they are only intended to show basic principles. Notice that when the voltage setting alone is increased greater physical penetration is achieved. The voltage parameter is one characteristic ofthe laser beam energy output. The laser must have enough energy to transport itself to the job site, meaning that it must overcome resistance of metal around the weld seam, and penetrate through the resisting metal so that it can access the inner faces of the seam.

Once the laser beam has penetrated to the job site it must have enough energy left in it to do the work (melt the surrounding metal). Notice in Figure I how increased volt- age alone creates an empty hole with little melting effect.

Changing Voltage

Another controllable energy characteristic is the duration that that the beam stays exposed in the metal over a single laser pulse, ("pulse duration"). Some correctly refer to this as "beam width". I think "pulse duration" better describes what is happening. Pulse duration is controllable on most machines in increments measured and expressed in milliseconds (thousandths ofa second). Leaving the laser energy exposed in the metal for longer heats the surrounding metal to its melting point and collapses the metal upon itself, thus fusing it together in a way that seamlessly joins the metal. Notice in Figure 3 that longer pulse durations melt a spot that is wider and deeper. Pulse duration can be used to gain penetration through melting rather than the

forceful physical penetration that is the result of voltage. However, longer pulse durations can bum certain metals leaving pits and brittleness.

Changing Pulse Duration

The laser beam requires different aspects ofenergy in order to penetrate than the energy required to melt. Voltage and pulse duration are directly related to the amount of energy (measured in joules) that is in the laser beam. Without discussing formulas of laser physics, I want to show the relationship between "voltage", "pulse duration" and "total energy". A direct relationship means that increased voltage or pulse duration equals more energy (joules) output in the beam, and a decrease in either two of those parameters equals less total energy in the beam. It is important not to forget that voltage and pulse duration are related to the energy directly, but the two individual parameters create different results.

Voltage is physical pressure that requires energy, and results in physical forceful penetration. Pulse duration is beam exposure time that also requires energy, and results in melting. Many machines have a display reading that shows a calculated total energy in joules, based on the selected voltage and pulse duration. I find that having a total energy reading on the display is not necessary but very helpful in understanding the characteristics and relationship of voltage and pulse duration. I commonly refer to voltage and pulse duration as the "energy settings". Often, when figuring out the best welding parameters for a particular job, I will note that energy must be increased, or decreased. One must then go one step further and ask what specific result ofthe energy should be different (penetration, melting, or both?).

Changing Voltage and Pulse Duration

The area in which the total energy is spread is a function of controlling the "beam diameter". Some correctly refer to this parameter as "focus". I like to call it "beam diameter" because a change in "beam diameter" at the viewing system focal plane is the effect that it has on the laser beam, as it applies to the current application forjewelry. It is important to understand the difference between the laser beam focus and the viewing system focus and how they relate to the parameters that I am discussing here. In fact, understanding the energy characteristics ofthe beam at the operators viewing system focal plain, goes hand-in-hand with learning the effect of the individual parameters.

I will discuss this in detail in the next article. For now, I'll just mention what effect changing the beam diameter has at the weld spot when the item being welded is held correctly and consistently in correct focus of the operator in the viewing system. Changing beam diameter changes the size of space that the laser's total energy is focused into. As seen in Figure 4, a given energy (voltage &milliseconds) in a narrow space or beam diameter will have a deeper effect in that small area than the same energy that is spread over a larger diameter. Changing beam diameter changes the joules per square area. Some machines display a calculated joule per sq. cm., based on the selected energy at a given beam diameter. I find that helpful in understanding the relationship between total energy and beam diameter.

Changing Beam Diameter

Figures 1,2, and4 show results from the three primary adjustable parameters: Voltage, pulse duration, and beam diameter, while they are being adjusted individually in an extreme manner. Figures 3 & 5 show results of adjusting two or more of these parameters simultaneously. All of these examples are not to any specific scale and are only intended to help explain basic principles.

Changing Voltage, Pulse Duration, and Beam Diameter

I consider voltage, pulse duration, and beam diameter to be the primary controllable parameters. Secondary to these three parameters is pulse frequency. A single laser pulse is initiated by depressing a foot pedal one time. Selecting a faster pulse frequency allows the operator to keep the foot pedal depressed and continue making laser pulses. Pulse frequency is usually measured and expressed in hertz (Hz).

"Hz" in this case, is the measurement of how frequently the laser pulses in one second. Machines that are available on the market currently range in Hz capability from 5 Hz maximum up to 20 Hz maximum. Increasing Hz delivers the pre-selected primary parameters at a faster rate per second. The results of a faster frequency will tend to be more aggressive than the same set of parameters in a single pulse, because the weld metal has less time to conduct the laser energy away from the weld joint between pulses.

These are the basics that can be learned through a small amount of experience working with a Laser machine. Knowing the relationship of the beam focus and viewing system focal plain, gaining eye-hand coordination, and learning how to make a continuous weld with and without filler metal, will be discussed in the next article.

See Also:

Laser Welding Basics - Part 2

Laser Welding Basics - Part 3

Laser Welding Basics - Part 4

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.