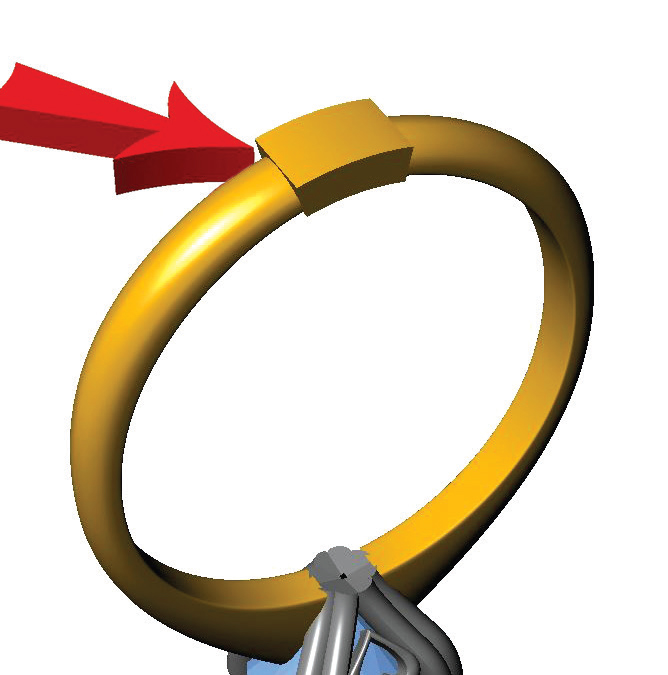

Step-by-Step Guide to Upsizing Rings

2 Minute Read

When I ran a trade shop, time was money, and I often found myself sizing 50 to 60 rings in a day. When you're doing that kind of volume, being able to quickly size up rings can make a big difference on your bottom line. Here's my technique for sizing rings up quickly, accurately, and with the least amount of waste.

Joel McFadden is a third-generation jeweler who learned the trade from his grandfather and other old-time jewelers in Charleston, South Carolina. He currently is the owner of The Art of Jewelry by Joel McFadden, a custom design jewelry boutique in Red Bank, New Jersey.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.