Palladium Annealing and Soldering

If you're just starting to work with palladium or interested in taking the leap, you should know a few critical details about its working characteristics. Palladium isn't difficult to work with; it's just different. Combining some gold habits with some platinum habits is the key to using this newly popular white metal at the bench.

2 Minute Read

Editor's Note: If you're just starting to work with palladium or interested in taking the leap, you should know a few critical details about its working characteristics. Palladium isn't difficult to work with; it's just different. Combining some gold habits with some platinum habits is the key to using this newly popular white metal at the bench.

Tools for Palladium Annealing and Soldering

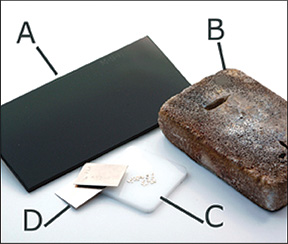

Palladium annealing and soldering operations require the use of a high-heat soldering block and shade five or higher eye protection. The same surface and eyewear you use for platinum should be adequate. Also, tweezers should be tungsten or ceramic, and soldering picks should be tungsten.

- A. Protective lens, shade five or higher

- B. High-heat soldering block

- C. Soldering pad

- D. Palladium solder

Annealing Palladium

Palladium is easily annealed with the use of a fuel-oxygen torch, with natural gas or propane and oxygen recommended. Flux is not necessary. Using the high-heat soldering surface and shade five or higher eye protection, adjust the torch to a slightly reducing flame, heat the palladium to a mild orange color, and hold for 10 to 30 seconds. The thicker the metal, the longer you must anneal it.

Polished mill products may lose their luster, but it can be restored quickly by polishing with white, blue, or green rouge. All work beautifully on palladium.

Removing Palladium Blush After annealing or soldering, palladium may exhibit what has become known as "palladium blush." This is simply a light layer of surface oxides that look green, purple, and/or blue. The oxides will wear off over time, but they can be removed easily by lightly heating the metal with a neutral flame for 10 to 30 seconds. Restore any lost luster with the polishing methods described above.

Soldering and Assembly When soldering, use the high-heat soldering pad recommended and gold or palladium solders, the latter or which come in easy, medium, and hard formulas. The best color match for 950 palladium is either 19.5 karat white gold hard solder or 20 karat white gold hard solder. Should you choose to use any white gold hard solder, you must use flux and firecoat. (When using palladium solder you do not need flux.) Clean, careful preparation of the joint is necessary to ensure good solder flow.

Additionally, if you use white gold solders take special care when polishing, as the solders are softer than the metal and can recede slightly during polishing if too much pressure is used.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.