Bead Setting Method – Part 1

6 Minute Read

Any name you wish to put to this method of securing stones works; but how many of you jewelry bench-workers know the real way of securing stones this way. Well, let me try and explain to you in the next two articles, starting now with its history!

"Bright-cutting" … a.k.a. cut 'n bead … a.k.a. pave'

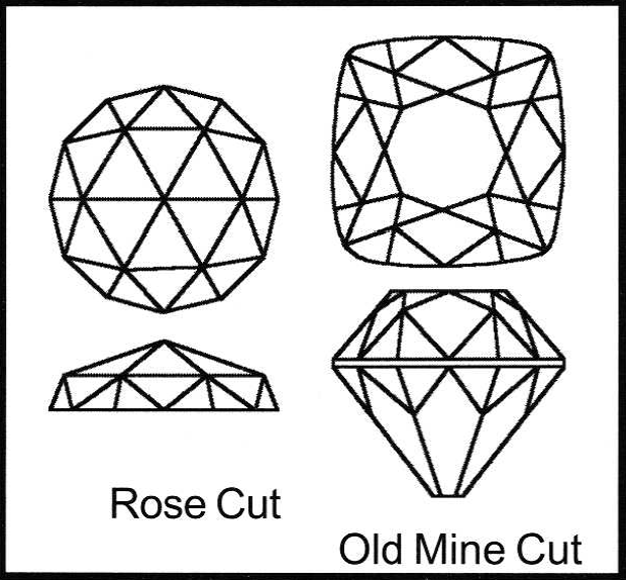

Years ago, we never had "flexible-shaft" machines. There were only "pump drills" and one had to cut open each and every hole with the use of a "Bull Stick". Can you imagine the tedium ofcutting open everyholeby hand? Imagine also an "Eternity" ring with 30+ diamonds and every one of them had to be fitted by hand with a very large #50 onglette graver, called a "Bull Stick". In those days of yesteryear, there were no regular shaped 57 faceted diamonds! We had only Old-fashioned cut stones, called "Meiner" and "Rose-Cut". Each of these stones were irregular shaped, and had corners or were dome shaped stones. The setter in those days had to really know how to securely set these rings. It took him about 3-4 hours to set just one Eternity Ring, let alone to do some fancy ornamental "Art-Deco" designed items.

The setter had to make his own gravers, bead raising tools, bead burnishers, and even make his own burrs. It's a far cry from just ordering what you need on the Internet and it comes to your front door the next day. Now that I've done some history for you, lets go ahead and describe what the setters of today have to work with. The basic diamond setting tools consist of #1 and#2 Onglette shaped gravers, #39 and #40 Flatbottomed gravers, and a vast assortment of burrs.

I use only two kinds of burrs: "bud" shaped and the "round" shaped for "bead-raising". I use every conceivable size ofbud burrs from #005 up till #030, and round burrs from #005, till #040.I always buy one or two dozen of EACH SIZE! That's in any case I get stuck for a particular burr. It's there at hand! There is no way I want to tell my client that I can't finish their work just because I don't have one small burr at my finger tips. Three or four times a year I make an inventory for my burr selection. If I find that one burr is slightly worn down, (teeth missing or grooves in the teeth from touching other stones while the burr tums) I discard it immediately!

My selection of tools must be totally organized with gravers and burrs. Not too mention, extra motors, hammers, and a bench grinder. I totally believe in my "back- up" system.

The first item on our agenda is one thing I stress with my students in my Gem-Setting class in Toronto. How far into the metal do I place the diamond for bead raising? Please have the "table" of the stone at the surface of the metal. The distance from the "table" to the "girdle" is the correct "rule of depth". This is now your guide in future setting.

If the diamond is too high, you will have a difficult time of "cutting " around the stones for cleanup and bright-cutting later in this process. The reason is that the girdle will totally hamper you in cutting around the stone, so being lowered into the metal is far easier on you, your gravers and your precious time. I use a round burr to accommodate the size ofthe stone. Once I feel and intuition tells me that the hole width is the right size, I "open" the hole for the pavilion of that stone with a "smaller" bud shaped bun.

Next, turn over the item to be set and"counter-sink" that underneath 'exit' hole. This will aid in the polishing procedure, you are now making available to have all of the polishing material to exit while its being cleaned after polishing. The "bud burr opening and the counter-sinking" drilling is very important, it gives more chance of exposure to that diamond while its in the Gold/Platinum. Plus the diamond won't "look dark or black" because of captured polishing refuse.

For the initial burr selection, I would prefer to use a 'fresh and new' burr as if I use an old one, the teeth of that burr will not give me the results I need in this fine drilling process. Do not over speed the burr as it's turning!

You might eventually drill right through the thin metal and or drill too low for the final seating of that diamond. One point that's important is to use a fine oil for all drilling processes. Oil prevents metal from 'sticking' to the burr and prevents it from doing the job it's intended to do.

Once you feel that the stone is sitting level with the surrounding metal, (check with your 10x loupe!) press the stone down with a copper or brass pusher until friction tight. Don't worry, you won't break the stone, but if you use a steel pusher, you just might! All you need is a light "tap", now to onto the next stone. Remember all the stones to be bead-set, must be LEVEL, SAME HEIGHTSECURE and above all, ALL IN A STRAIGHT LINE.

Once this is done, we can now proceed to the next step!

Well now, the actual process of raising beads can be written in one sentence. Forming gold over the girdle of the set stone and observing to see if the girdle of that stone is well covered.

Grinding ofyour gravers is one of the most basic things to learn. Plain and simple - The bead raiser is made from a#2 Onglette graver by making it just a tad thicker at the leading edge or point by rounding off the underneath side. The graver MUST have the underneath thin edge rounded off. Why? When you are attempting to form a bead, the graver won't break along that thin "underneath edge".

Where do you start to raise a bead? Very interesting and also very important question. Imagine that you are drawing a square or picture frame around the round diamond. Now at these 'four corners " or points, is where you make the four beads.

Start in one corner and raise the first bead. DO NOT RAISE IT SO IT'S OVER THE STONE YET! You should only raise it so its AGAINST the stones' girdle, now on the opposing corner is where you raise the bead fully and return to this first one and form it back over the girdle. The "first bead" secures the stone from sliding out as you raise the second bead!

CHECK WITH A 10 POWER LOUPE! Now at this point do the same with the other two un-beaded corners. Again, check with your loupe! If you have many stones in a row, raise the first beads on ALL OF THE STONES AT ONCE. Then come back and raise the second securing bead. Why do it this way? By raising beads in this manner "the angle of raising beads" is the same with all of the stones, they will all be uniform and in line.

The next step in this procedure is to "rough-cut" or line cut, with a#2 onglette graver or maybe a #l onglette graver, only if you feel confident with this thinner graver. Once you start to make the first cut, all of the metal will be removed from around each diamond. Beads must not be removed in this cutting process. The only criteria is that the "under belly", as well as the point of the graver MUST be always sharp. This sharp edge acts as a "metal separator" as this tool now acts as a guide for the next step, "bright-cutting"…!

This next process will be discussed in the next issue!

See Also:

Bead Setting Method - Part 2

Bead Setting Method - Part 3

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Gerry Lewy

With over 40 years experience as a stone setter, Gerry Lewy is known throughout the diamond setting community. Gerry started his 9-year apprenticeship with a jewelry manufacturer and tutored by a gentleman ‘setter’, in Haddon Gardens, London. Gerry has redeveloped himself into more than a master setter, his purpose is now to be a teacher of the art as well.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.