Spot Welding Devices for Goldsmiths

3 Minute Read

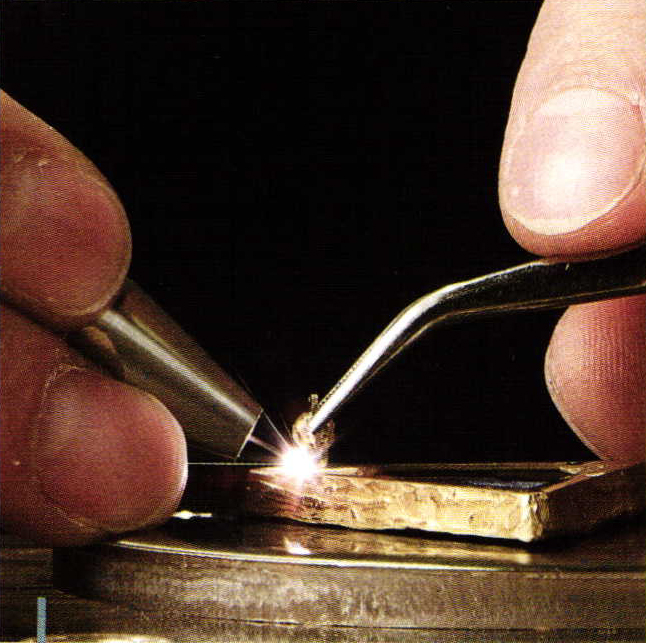

Spot welding devices have become quite popular on the market and are indeed now indispensable features in many goldsmith studios and production firms. Instead of elaborate soldering on the item of jewelry and heating up the entire jewelry metal, the advantage of electric spot welding lies in the targeted application, enabled by the light arc. The precision of the welding, the simple application and the time savings in assembly to repair of jewelry items enable efficient working. Roughly three years ago, Lampert Werktechnik introduced to the market a spot welding device, the PUK. Lampert is now presenting the second spot welding device, PUK 2. It unites many features that laser welding devices also offer.

Optimized version for all requirements

The improved version of the PUK 2 has all the features of its predecessor, the PUK 111, but now has an enhanced performance. Indeed, it can offer up to 30% more in terms of performance, which leads to quite a few advantages. A higher impulse rate of 17 seconds also reliably welds silver, which as we know is a good heat conductor. The device's two most important functions, the welding frequency and the impulse length can be controlled using two switches. A higher setting for the impulse length enables a greater penetration depth whenever necessary, which leads to a greater strength of the welding points in addition, the welding points can be structured with greater fineness. A high performance adapter shortens the welding frequencies, and work on the jewelry can be carried out faster as a result. In this, the thermal effects of the light arc on the work piece remain very low. The work piece can therefore be held in the hand without any problems; also, welding close to a gemstone or on jewelry that has already been polished does not have any major repercussions.

Operating the device takes experience

The small and compact PUK system includes a welding table, a grip and holder, a selection of clamps and an optical unit. The work piece should be well positioned on the welding table in order to ensure there is an optimum electric contact. If this is not possible, a clamp can make the electric contact to the PUK Depending on the selected working situation, the clamps or the welding table are connected to the PUK device. The welding should only be observed through an optical unit that darkens automatically. The welding process itself is automatic The sharp electrode located in the handle closes the electric circuit when it touches the jewelry metal and starts the welding procedure. A short light arc is emitted from the point of contact. The metals melt with a small and stable welding point of 0.6 - 3 mm diameter. The welding point penetrates deeper into the metal, the higher the welding performance and the less thermal conductivity the material can offer. A protective gas prevents oxidation on the jewelry metal during the welding process. During welding, additional, suitable material in the form of a wire with 0.3 mm thickness can be added to the jewelry or work piece. Experienced users will also find it easy to close pores. In general, the welding result is dependent on the metal's melting point and thermal conductivity. Like with all new methods, novice users are recommended to carry our trial welding on various metals and with different degrees of intensity, as the results and the quality of the welding are dependent on many factors. Different metals and alloys behave very differently indeed during welding. The metal characteristics such as conductivity, melting point and any possible, slightly volatile alloy elements have significant effects on the results of the welding In general, all standard and known precious metal alloys made of gold, silver, platinum and palladium can be welded This also includes trend metals such as stainless steel, titanium or steel-cobalt alloys.

Lampert Werktechnik is now a familiar name in the United States thanks to the PUK. The AJM Magazine, a publication by manufacturers of jewelry and suppliers of the American jewelry industry awarded Lampert the Innovation Prize for the PUK 2. Eleven independent jurors from the jewelry industry selected the trendsetting product. The prize also comes with eligibility to participate in the Innovation Exhibition Area at the MJSA 2005 Expo New York in March of next year.

by Susanne Heuer

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.