Production Jewelers: Design, Marketing and Business

8 Minute Read

This is the fourth in a series of articles from Metalsmith about production jewelers: design, marketing and business.

*************************

| Business Name: | Diana Vincent Co., Bucks County, Pennsylvania |

| Designers: | Diana Chrambanis and Vincent Polisano |

| Description of Jewelry Line | |

| The clean mechanics and high-polished look of classic fine jewelry in 18k yellow gold and platinum with diamonds and colored stones. The line has been selling for three years and new pieces are added to it as they are designed with little acknowledgement to trend or fashion, or even specific markets. Except for some casting, all work is made in-house to ensure quality. | |

| Business Setup | |

| A partnership that employs three full-time employees, all with backgrounds in art metalsmithing. Because this work is high-end—earrings can retail from $400 to $3,500 and necklaces from $2,500 to $6,000—it does not sell well at craft fairs. DV shows twice a year at the Retail Jewelers of America Show and also personally takes work to galleries and stores. Pieces are sold wholesale, as well as on commission, and the line is advertised nationally and internationally. | |

| Education | |

| Vincent Polisano was trained in the jewelry industry and served as an apprentice; Diana Chrambanis received a BFA from the Tyler School of Art where she majored in metalsmithing. Not surprisingly, though neither has had strict business training, Vincent feels that his experience in the industry prepared him adequately for his vocation. | |

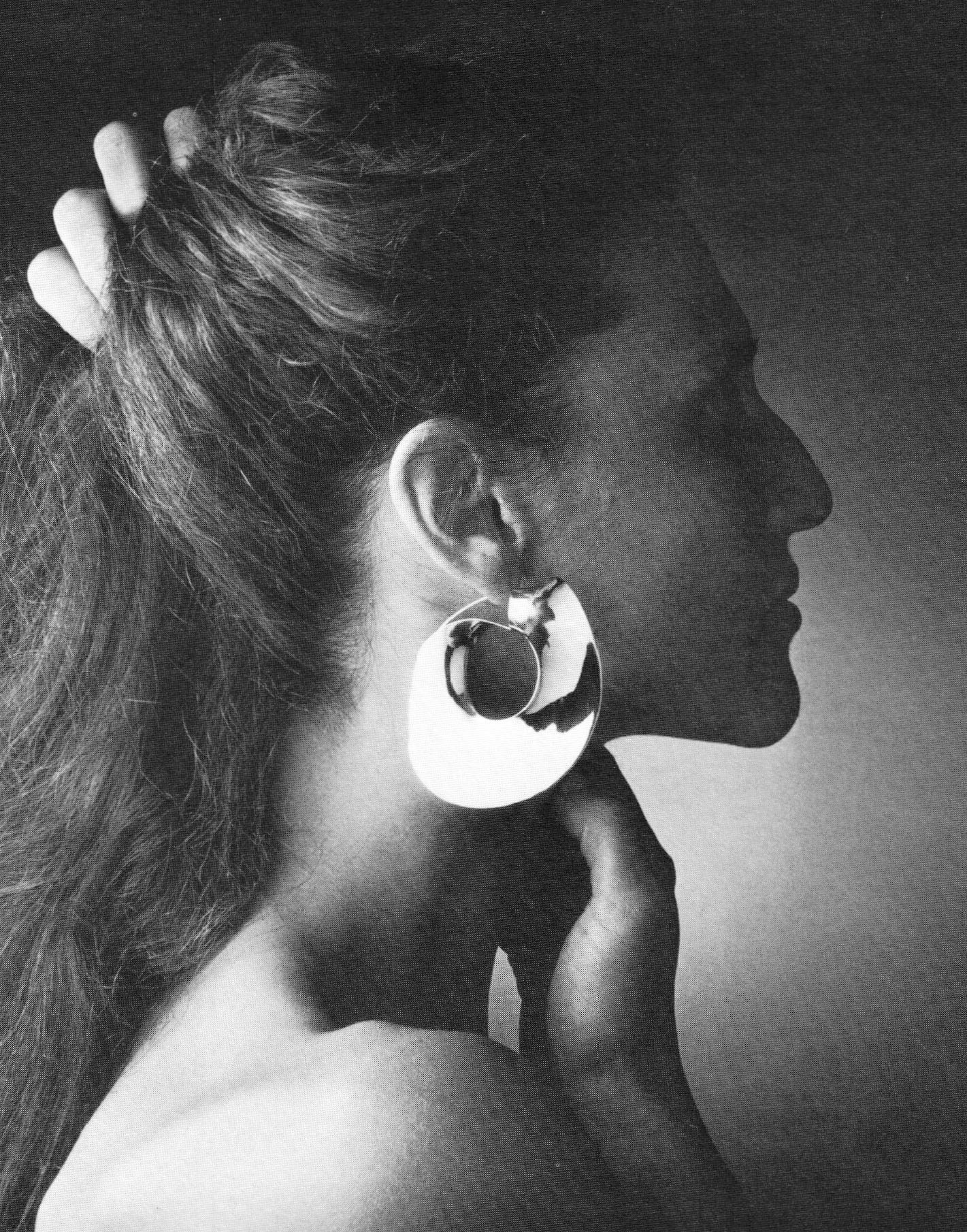

| Business Name: | TKO, Milwaukee, Wisconsin |

| Designers: | Alice H. Klein |

| Description of Jewelry Line | |

| The line straddles high fashion, art and costume jewelry, though it remains visually different from commercially costume jewelry. The clean, tailored lines are executed in acrylic, mother-of-pearl, Formica Colorcore, cubic zirconia and gold-filled or sterling wire. Both materials and process continue to reflect an intrigue with industry. Designs are updated four times a year, partially in recognition of fashion trends. "Ultimately," says Alice Klein, "one would like to become known for products that are changing visually every year, but also retain a style and visual continuity that is unique to oneself. Style is how one synthesizes formal ideas and visual elements through one's materials into objects that demonstrate a highly personal manner of approaching and solving visual problems. If one has a strong sense of personal style, it will permeate all the products one makes."When we first started there was a general trend in the craft market, circa 1978, which featured a machined, cool, geometric 'high tech' look. We were using plastics, base metal and sterling silver-inspired cast components that required a great deal of time to fabricate and finish. People were unaccustomed to seeing and paying for plastics combined with base metals or sterling in a cool, tailored manner. Comments generally heard were: "Is this plastic? It's so expensive!" As time went on, the audience gradually developed an understanding of plastic jewelry. "Good As Gold," organized and curated by the Renwick Gallery of the Smithsonian Institution, helped educate the customer and collector to the use of alternative materials. We preserved with showing our product at the ACC Fairs and the Philadelphia Craft Show and we found that our audience was growing by seeing our jewelry as well as that of people like: Vincent Street Studios, Julie Shaw, Thomas Mann, Pinpac Studios, etc. In the past two to three years we've seen interest in the fashion world of accessories that are fresh and arty looking. So one is straddling both worlds of fashion and art by creating a product that is visually different from commercially manufactured costume jewelry. Since being in the art fashion jewelry area our lines have become less labor intensive than they used to be. Price point is crucial if one wants to sell production jewelry. Boutiques, clothing stores and craft galleries are interested in a product selling as soon as possible. One must create visually exciting jewelry in the most economical way. The production work is one part of an entire product line that also includes limited production and unique pieces. The production work acts as a bridge to the one-of-a-kind. | |

| Business Setup | |

| TKO is a partnership between Alice Klein, who designs the line, and her husband, Wyatt Osato, who handles marketing and sales. Ninety percent of the work is sold wholesale, through exposure at craft fairs and trade shows, "a must for finding new accounts and being seen." Direct solicitation and promotional mailings have also proved to be effective marketing tools. The firm employs five part-time employees in the studio. A full-time accountant and mechanical engineer, together with Klein and Osato, make up a planning team to address the direction of business, sales and design. That TKO has a clearly defined set of goals is among the most important aspects of their business. | |

| Education | |

| Alice Klein received a BFA in metals from the University of Wisconsin and an MFA in metals under Stanley Lechtzin at the Tyler School of Art in Philadelphia. "During graduate school Stanley Lechtzin informed us that there was a scarcity of tenured teaching positions available. So in keeping with the reality of the job market, he devised a production curriculum that was to develop an attitude and method in the creation of production jewelry. Besides the production curriculum he also offered a teaching program. I chose the production program." Her business training has been acquired through experience. | |

| Business Name: | David LaPlantz/David D. Deco, Bayside, California |

| Designers: | David LaPlantz: |

| Description of Jewelry Line | |

| The line tends towards high fashion, wearable art. Nonprecious materials—anodized and painted aluminum, leather, plastics, found objects, rubber—form colorful constructions that acknowledge fashion, though not necessarily fashion trends. A sense of style, color, variety and timing influence more than seasonal styles. New designs are developed on a daily basis, and LaPlantz puts a high value on risk-taking and the inevitable excitement that comes with making samples and spin-offs that develop into their own series. The line is three-and-a-half years old and addresses a middle-end market, which LaPlantz looks to with assurance: "The public has stayed loyal to David Bowie," he points out. "So why not me?" | |

| Business Setup | |

| LaPlantz makes 90 to 95 percent of his work; the remaining few parts and pieces are found objects. He is the sole owner of his business and has no employees. He enjoys being able simply to depend on himself and so keeps productions to between 300 and 500 pieces per year, which for the most part are sold wholesale, although some are sold on consignment and a few on commission. LaPlantz never attends craft fairs or expos, finding that he is able to do sufficient business with galleries and stores through the mail or personal visits. Likewise, he has found that reps "never deliver what they promise." In discussing pricing, LaPlantz says, "First, I like to see just what the competition is like. I usually say, 'Hey, I can do better than that and for a better price.' Then I set out to prove my theory to be correct. Why not be cocky? I try to make certain value and design for a certain price. I don't make any earrings for under $30 retail. I don't find it worthwhile making lower priced work. Since my metal (aluminum) is inexpensive, I can afford to create works that can sell for less than my competitors. My overhead is low and my manufacturing time is short. I endeavor to make low-priced, high-fashioned, wearable art pieces that a larger percentage of people can afford. The colors and design will evoke a spark of excitement in the wearers and the viewers. I work fast and try to pay myself anywhere from $18 to $27 per hour. I must work fast to do this. Considering that I teach and work at school for a least 30 to 35 hours per week, I can't afford to waste any of my time." Time is perhaps his most valuable commodity, and it is one he uses economically. Because of his teaching at Humboldt State University, the time spent constructing pieces, pricing, packing and doing paperwork is managed efficiently, sometimes even with a stopwatch. Likewise, uneventful faculty meetings are a time to catch up with client correspondence. LaPlantz finds that teaching balances well with making the pieces. "Both create new stretches of the imagination, much like a ligament allows us to stretch our arms and legs, to walk better, and more upright." | |

| Education | |

| LaPlantz attended Bowling Green State University in Ohio and did graduate work at Cranbrook Academy of Art. Workshops he has taken and taught make for a continuing education program, as does simple experience and "flying by the seat of the pants." | |

| Business Name: | Timothy Grannis, Essex Junction, Vermont |

| Designers: | Timothy Grannis |

| Description of Jewelry Line | |

| Classic art jewelry, with fluid, curved forms that reflect the designer's background and continuing practice in sculpture. The pieces are lightweight, comfortable, wearable. Highly polished, they bear little evidence of the handwork that has gone into their manufacture. Available in 14k gold or sterling, the line has been selling for nine years. A few designs are added each season. Because Grannis's design style is reductive, new work appears only after a long period of development; a production line, then, is what makes it profitable. | |

| Business Setup | |

| Apprehensive about training more people in the hand skills in his forming techniques, Grannis works with only one part-time assistant, whose background is in flute building. Pieces are sold wholesale with pricing formulas established by bench time, materials and materials markup. The line is shown at numerous craft fairs, including ACE shows and annual shows sponsored by the Smithsonian, as well as the WBAI Fair in New York City and the Philadelphia and Morristown craft shows. | |

| Education | |

| A studio art student in college, Grannis received little formal training in metalsmithing. A workshop with Heikki Seppä, however, was extremely influential in his use of shell-forming techniques. | |

Related Articles:

- Production Jewelers: How They Survive

- Production Jewelers: Design & Industrial Techniques

- Production Jewelers: Marketing Production

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.