Debunking a Soldering Myth 1

2 Minute Read

After 25 years as a jeweler, first as a student, an apprentice, an instructor, and now a master instructor and director of the Jewelry Arts Institute in New York City, I've come to realize that much of the basic information about soldering being taught to students is misleading and confusing.

There are many myths about heating pieces during soldering that can cause innumerable problems during relatively simple soldering operations. In this new occasional column, I will address the top soldering myths and the essential criteria to be used in evaluating soldering techniques.

Soldering Myth Since the cone is the hottest part of the flame, you should use it for soldering

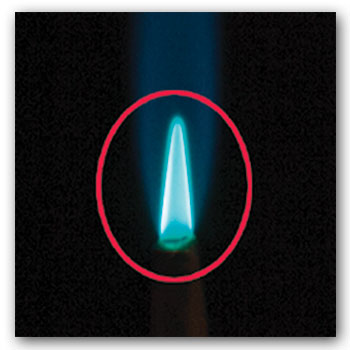

Almost any beginning jewelry student can tell you they have read or been told by instructors that the hottest part of the flame is the cone (Figure 1). This is factually accurate. However, there is a difference between the part of a torch flame where the temperature is highest and the part that can transfer the most heat to the work.

The trouble comes when students interpret the cone being the hottest part of the flame to mean they should try to place the cone of the flame as close as possible to what they are trying to heat (Figure 2). This is ineffective, causing the majority of the flame's heat to be released beyond the piece and leaving the students to wonder why their solder oxidizes and refuses to flow.

After doing repeated testing in the studio over many years, I've found that pieces heated with the end of the flame (Figure 3) reach soldering temperatures more quickly because they are receiving all of the flame's heat, rather than just the heat from the cone. There's also less oxidation than when the cone of the flame is used because the piece heats faster.

In addition, using the end of the flame gives you more control over the heat. When soldering, you want to withdraw the heat as soon as the solder has flowed where you want it. If you don't cease heating, the solder will continue to flow, possibly to where you don't want it.

I've found that the natural reaction to remove the flame is to pull it back up, not off to the side. If you're heating with the flame's cone (Figure 4), pulling it up will leave the rest of the flame heating the joint for an extra second or two. This additional heating time could mean the difference between a perfectly soldered seam and a sloppy, overheated seam with pits.

To help avoid this, position the torch as illustrated in Figure 5, using the far end of the flame to heat the seam. This positioning will provide the ideal situation: fast and controlled heating.

Editor's Note

This article is excerpted from "Soldering Demystified," a paper presented at the 2015 Santa Fe Symposium on Jewelry Manufacturing Technology. To order a copy of the paper, visit santafesymposium.org.

Ganoksin Staff Note: Finding The Best Soldering Tools & Supplies

You can greatly improve your soldering results by following the tips and techniques outlined in this article. However, some issues may be the result of using the wrong tools. You can find in-depth reviews and current recommendations of all the best soldering tools and supplies in our Buying Guide section:

Best Soldering Station Reviews

Best Soldering Third Hand Reviews

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.