Changing Ring Widths and Saving Time

1 Minute Read

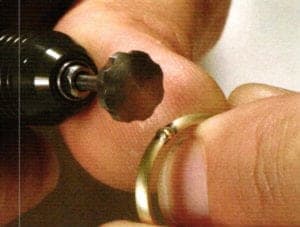

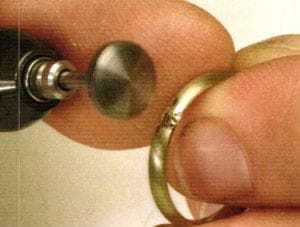

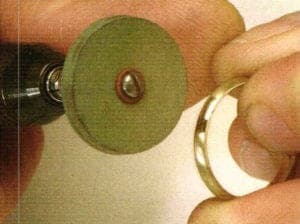

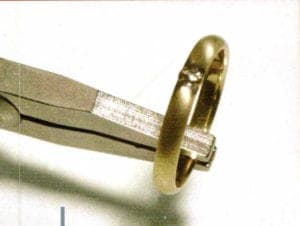

Heatsensitive gemstones must no longer be removed from their setting when changing a ring size. This provides the goldsmith with immense time advantages. When joining the ring back together by welding instead of soldering the heat development is so low that the gemstone is not affected. The welding procedure is demonstrated using a simple ring made of 14 karat gold and the most practically tried and tested device PUK 2. www.lampert.info

by Christine Patrich