Beading Tool Tips

Like most bench jewelers I do a lot of bead setting and like most

bench jewelers I take pride in my work. When I bead set I want crisp

and clean beads. Recently, I was setting one pointers into white

gold skirts that would become a pair of earrings. I hadnt gotten

very far when I noticed that the beads were getting raggedy and

there was quite a bit of finning between the edges of the bead and

the melee. I knew this meant that my beading tool was becoming dull.

I would like to share with you a tool tip for sharpening a worn out

beading tool.

2 Minute Read

Like most bench jewelers I do a lot of bead setting and like most bench jewelers I take pride in my work. When I bead set I want crisp and clean beads.

Recently, I was setting one pointers into white gold skirts that would become a pair of earrings. I hadn't gotten very far when I noticed that the beads were getting raggedy and there was quite a bit of finning between the edges of the bead and the melee.

I knew this meant that my beading tool was becoming dull. I would like to share with you a tool tip for sharpening a worn out beading tool.

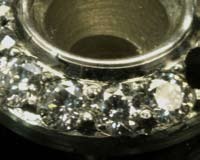

This picture is of a dull beading tool. The tool has been used to set about ten stones, which is approximately 30 beads. You can see that the edge of the tool is rounded from having come in contact with melee. A tool that is worn like this one cannot produce a good bead and will leave a raggedy edge.

The problem has always been that beading tools are made of hardened steel and thus difficult to sharpen. Traditionally, these tools were heated to soften the steel then they were tapped into a beading block and finally re-tempered. This process is so time consuming that today most bench jewelers simply throw the tool away and buy a new one. I've got a less expensive way.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.