Soldering Parts Using Pourable Soldering Jig

There is a great way of doing very complex and repeated solderings in one go. This very important method uses casting and soldering investment is to set up multiple solderings at once. The idea is that you take clay (I prefer real clay, not plasticine - less oil and grease present to impede soldering) and make a 'bed' of it, a slab. Some people like to use a soft wax like 'BonBell' wax that covers small round cheeses instead of clay.

2 Minute Read

There is a great way of doing very complex and repeated solderings in one go.

This very important method uses casting and soldering investment is to set up multiple solderings at once. The idea is that you take clay (I prefer real clay, not plasticine - less oil and grease present to impede soldering) and make a 'bed' of it, a slab. Some people like to use a soft wax like 'BonBell' wax that covers small round cheeses instead of clay.

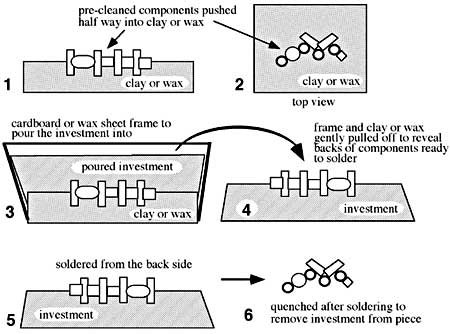

You take your jewelry components, pre-sanded and clean, and press them carefully into the clay (or wax) as you want them to appear when soldered together. That is, pushed tightly next to one another and to the half-way depth in the clay or wax. Then walls of some kind are built around the clay slab. Usually these are cardboard and duct tape or built using clay. Dentists would use 'boxing wax' for this job, this is the standard pink sheet wax that jewelers use to make jewelry models with, never suspecting its main purpose is to build 'boxes' for pouring investment into.

Casting or soldering investment is then poured into the frame and allowed to set. When dry the frame and clay is carefully peeled off revealing the back halves of the components sticking out of the investment. When the investment has been allowed to dry out (which is very fast with Quickset #2 soldering investment and slower with casting investment) the protruding components are fluxed and soldered in one operation.

Finally the whole thing is quenched in water to remove the investment. Any remnants are brushed away under running water. Malika Hemachandra, a Sri Lankan I met in Colombo did this with hundreds of components at one time, one giant soldering job for innumerable stamped and cast parts and settings in one go.. She was making large, very complex neckpieces with dozens of stonesettings and hundreds of parts, all done with one soldering operation. She used an iron bust to set up the clay and investment soldering jig.

When I worked in a German factory in Pforzheim we used the same idea to make reusable soldering jigs with casting investment. Our jigs consisted of one third casting investment, one third Portland Cement and one third fibrous refractive material (ok-we used asbestos back then, these days you would use Fiberfax or a similar ceramic fiber). These jigs were for a repeatable production soldering set up. We would make the clay slab, set the components in, build the walls and pour the jig mixture in.

An interesting addition was to use broken sawblades as 'rebar' in the jig. When the jig mixture was halfway poured in broken sawblade pieces were sprinkled into it, and then they were buried as the mold frame was filled up with the investment mixture. They acted like the knobby iron rods use in concrete to increase strength: Rebar. This meant that even if the soldering jig cracked in use the webwork of broken sawblades within kept it from falling apart. Generally we could get about 50 solderings from such a jig before it broke down too much to use. So, at last, an excuse to keep your broken sawblades….

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Charles Lewton-Brain

Master goldsmith Charles Lewton-Brain trained, studied and worked in Germany, Canada and the United States to learn the skills he uses. Charles Lewton-Brain is one of the original creators of Ganoksin.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.