Resolving Surface Irregularities in T-Splines

2 Minute Read

T-splines, a plug-in for Rhinoceros CAD software and bundled with Matrix 7 and above, is a great modeling tool for freeform designs. In the jewelry industry, T-splines makes it possible to create on-the-fly, continuous curvature surfaces that are difficult to make using traditional surface modeling techniques.

Resolving Surface Irregularities in T-splines Using Rhino Commands

T-splines handles sculptural models especially well, including organic jewelry pieces that incorporate animals, plant life, and human figures.

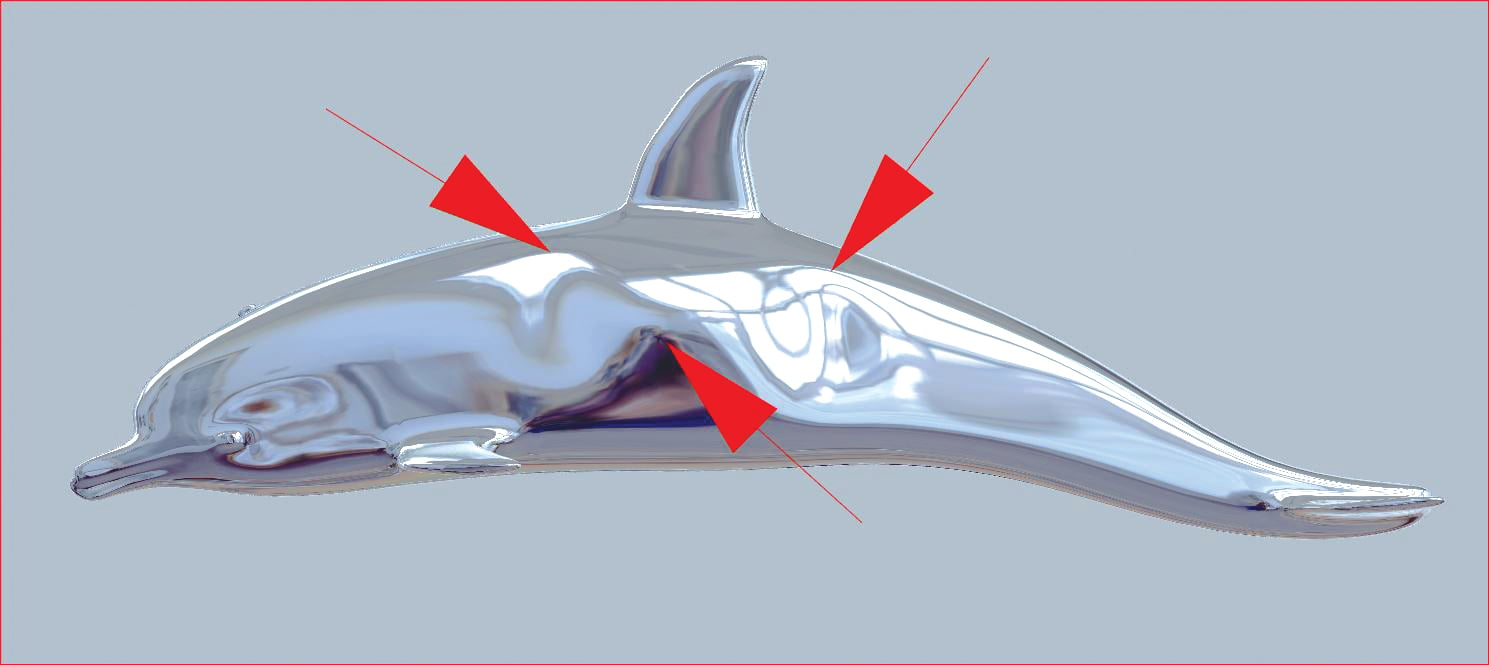

The indentations along the side of this dolphin charm, for example, are clearly noticeable (right top). The "EMap" (environmental map analysis) command reveals discontinuities in the curvature of the surface, indicated by the red arrows.

Resolving this issue is often difficult. Pulling and pushing faces, edges, and vertices in T-splines can be tedious, time-consuming, and, ultimately, unfruitful. In fact, it can sour your experience with the program if you are used to the continuity Rhino offers. Using a degree 3 Rhino surface as reference, however, eases the process of smoothing a T-splines model.

Begin by mentally isolating the area with the deformation. In this case, it is the mid-section below the fin and behind the flipper. Use the "curvature analysis" command to assist in determining areas with surface discontinuity. The areas in blue and red show where the surface bulges and dips, distorting the side of the model.

With the point snap on, place Rhino point objects along the ends of T-splines edges in a loop just above the distortion and along the ends of two loops of edges just below the distortion. Each row of point objects should be alongan equal number of edges. Creating a total of three rows will become important in a later step.

Use the "curve through points" command to create a curve through each individual row of points. Be sure to choose "degree 3" from the command line so the surface created next will be degree 3 curvature continuous.

Loft the three curves. The three curves will follow the curvature of the model; if you use only two, it will default to "straight sections" and won't follow the surface. Note in the example how the smooth Rhino surface intersects with the irregular surface of the model.

Extract an isocurve from the Rhino surface near the loop of edges on the T-splines surface that does not have Rhino point objects. The isocurve should run parallel to the Rhino curves created for the lofted surface.

Use the T-splines "match" command to select "midsurface" from the command line and then select the loop of edges nearest the extracted isocurve and parallel to those used for placing point objects. Next, select the isocurve extracted from the Rhino surface. Depending upon the preview, it may be necessary to select "alignment" from the command line and then "flip alignment direction."

Once the preview curves are aligned perpendicular to both the Rhino curve and the T-splines edge loop, press enter. The T-splines surface will shift in line with the Rhino surface. When you apply another curvature analysis, it reveals that the areas that were once red and blue are more uniformly green, denoting a smoother curvature.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.