Origins, Evolution and the Practice of Enameling

12 Minute Read

More than 3000 years ago, someone spread powdered glass onto metal, probably gold, and subjected it to sufficient heat to cause it to soften, wet the surface, spread and adhere. We will never know exactly where or when it happened or exactly what material was first used. A chunk of glass taken from a broken clay crucible in which the glass was smelted may have been used or chip of glaze from a clay pot. No matter how it first happened, this process has been handed down to us as enameling.

Origins, Evolution and the Practice of Enameling

Enamel is only one of the several names used to describe variations of the same material. When changed slightly and applied to a clay pot, it is called a glaze. When it acts as a binder for the crystalline material in a pottery vase, fire brick, floor tile, dinner plate or abrasive grinding wheel, it is called a vitreous bond. When this material is formed into a large thin sheet and inserted in a wall, it is called window glass. And when this glass is applied to metal, it is called enamel.

The word "glass" refers to a state of matter, as well as a product. We are actually talking about the "glassy state," a state of matter possessing several unique properties. One of these properties can be demonstrated by thermal analysis. A thermocouple is inserted into a molten mass and its temperature is measured at intervals as the mass is slowly cooled to a temperature below its melting point. Plotting the temperature against time results in a cooling curve.

Figure 1a shows the cooling curve for a crystalline material. A temperature arrest occurs at the melting point. The duration of this arrest is the time required to completely crystallize the material. Many liquids react in this manner: pure metals, water and most pure chemical compounds.

Figure 1b shows the cooling curve of glass. There is no arrest point, nor distinct melting point. The decrease in temperature is a continuous curve—it is noncrystalline.

Another important property of glass is its continuous change in viscosity. For all practical purposes, it is a solid at room temperature. Most inorganic materials, including metals, have an instantaneous and drastic change in viscosity at their melting points. The unique properties of glass are a result of its structure. Man has made glass for at least 10,000 years. However, it was not until the second quarter of the present century when we began to have some understanding of its structure. Although much progress has been made, the exact structure of glass is yet to be determined.

Over 99% of the glass made throughout history has contained silica as a major constituent. The structure of silica glass is a random three-dimensional network of silicon-oxygen tetrahedrons. The tetrahedrons consist of one silicon ion surrounded by four oxygen ions. The tetrahedrons share corners, not edges or faces, in forming the random network. Most people are surprised to learn that 70 to 90 percent of the atomic volume of glass is oxygen. Alkali and alkaline earth oxides weaken the silicon-oxygen network by supplying extra oxygen ions, which make the network more random. The result is a lower viscosity at a given temperature, or a glass with a lower softening point. The alkali and alkaline earth ions occupy the interstices or holes in the network, migrating easily even at room temperature if subjected to an electrical field. They are classified as modifiers. Boron and phosphorus can enter the network and are classified along with silicon as network formers. Aluminum, titanium, zirconium and other ions can function either as network formers or as modifiers; thus they are classified as intermediates. At least 70 elements can be glass constituents. A glass seldom contains less than three elements. Enamels are complex, and it is not unusual for them to contain 10 to 15 elements. Since any change in a constituent makes a different glass, there is an almost infinite number of compositions.

Enamels are made by weighing and mixing ingredients such as silica, feldspar, sodium nitrate, borax, potassium carbonate, lead oxide, titanium dioxide, cobalt oxide, etc. The mixture is loaded into clay crucibles and heated to a temperature of about 2200°F, where the ingredients form a melt. The nitrates, carbonates and borax are the first to melt, forming a liquid that takes the rest of the batch into solution. The smelting is continued until all bubbles have been eliminated. The molten enamel is ladled or poured onto steel slabs to cool or into cold water, where it shatters into small pieces. In the latter case, the small pieces are called frit.

The next step is crushing and grinding the enamel to a particle size suitable for the selected method of application. Steel rolls are used to produce dry powder of a specific particle size. Water and suspending agents can be added to form a creamy liquid. Enamel can also be ground with light oils for certain applications. When selecting an enamel for a particular metal and application, you must consider three primary properties of the enamel.

- Fusibility and fluidity

- Resistance to the intended environment

- Thermal expansion and contraction

By fusibility, we mean the temperature at which the enamel starts to soften. Fluidity is the reciprocal of viscosity. The enamel must be fluid enough to spread across the metal surface when fired at a temperature appropriate for the metal being coated. Obviously, an enamel that softens at 1400°F is not suitable for application to aluminum that melts at 1232°F. Enamels can be formulated to fire at temperatures from about 900°F to 1850°F. Within limits, firing is an inverse relationship of time and temperature. That is, a particular enamel may fire equally well at 1350°F for 5 minutes or at 1500°F for 1½ minutes, while at 1250°F, it would never fire out. In this case, the enamel has a firing range of about 150°F. This range is typical.

If the finished product is to be exposed to the weather, the enamel must be weather resistant. If a part of the product is to be plated after enameling, the enamel must be resistant to the plating solutions. Resistance to various environments is a matter of enamel composition.

Thermal expansion and contraction must be compatible with that of the metal or the coating will chip or flake off. The effect of expansion and contraction can be more readily examined and understood if we consider a metal strip enameled on one side. Figure 2 shows the relationship between enamel and metal as they cool to room temperature.

Figure 2a shows the strip just as it leaves the furnace. Since the enamel is fluid at the firing temperature, it easily adjusts to fit the dimensions of the strip. Figure 2b shows the hypothetical situation if it were possible to separate the enamel and metal into two individual layers just as they left the furnace in a. Continuing with the hypothetical situation, Figure 2c shows the relative reductions in lengths of the enamel and metal when they reach room temperature. The enamel contracted less, just as it was designed to do. Figure 2d shows what actually happens, since the enamel and metal are bonded together. Note the length of the composite is a little longer than that of the metal and a little shorter than that of the enamel in c. Obviously, the metal is trying to reduce its length further, but the enamel prevents it. The enamel is in compression and the metal is in tension. Figure 2e shows that the composite will bend, trying to counteract the stresses, if only one side is enameled.

Applying the same amount of enamel on both sides of the metal will greatly reduce the bending caused by this differential. However, enameling both sides of the metal does not eliminate the stresses in the composite. The stresses are proportional to the difference between the coefficients of expansion of the metal and enamel. With enamel being strong in compression and weak in tension, it is mandatory that a level of stress be present in the composite to insure the enamel is always in compression.

Figure 3 illustrates what happens if these stresses become too great. The problem develops first on convex radii. The enamel fails in tension but the concentration of compressive forces provides the push. To successfully coat any given metal, the enamel must be formulated to have a coefficient of expansion within a certain range based primarily on the coefficient of expansion and modulus of elasticity of the metal.

After determining the three physical properties of an enamel are such that it can be applied to the selected metal, other properties such as color, gloss, texture, etc. can be considered. Unfortunately, many enamelists start with the color and give little, it any, consideration to the three primary properties.

There are some limitations on the condition of the metal surface prior to application of enamel. Perhaps the most misunderstood principle is the fact that some oxide must be formed on the metal during firing but no more than the enamel will take into solution. In general, the surface must not have an oxide layer in excess of what the enamel can dissolve during firing. The surface must not have even a small amount of oxide that does not adhere tightly to the parent metal when heated to the firing temperature. The surface must not have organic matter that will leave an appreciable amount of ash at the firing temperature.

Preparing the surface can be as simple as heating at a lot temperature to burn off light oil, followed by a light brushing to remove any loose oxide. It can be as complicated as using a combination of degreasing, acid pickle, bright dip, rinsing with deionized water, scouring with various abrasives, neutralizing and drying with hot air. Abrasive blasting is occasionally used. Metal preparation should be as simple as the final desired effect will permit. Contrary to popular belief, roughness of surface is not very important.

Art enamlists usually apply enamels by wet charging or by sifting. It may also be brushed, using either water or oil as a vehicle. If ground with water and a suspending agent, the liquid can be applied by pouring, dipping or spraying. Industrial enamelers coat cast iron bath tubs by first heating them in the furnace, removing the red hot tub, sifting enamel powder on it and then replacing the tub in the furnace until it is properly fired. Some metals cannot be enameled in any other way.

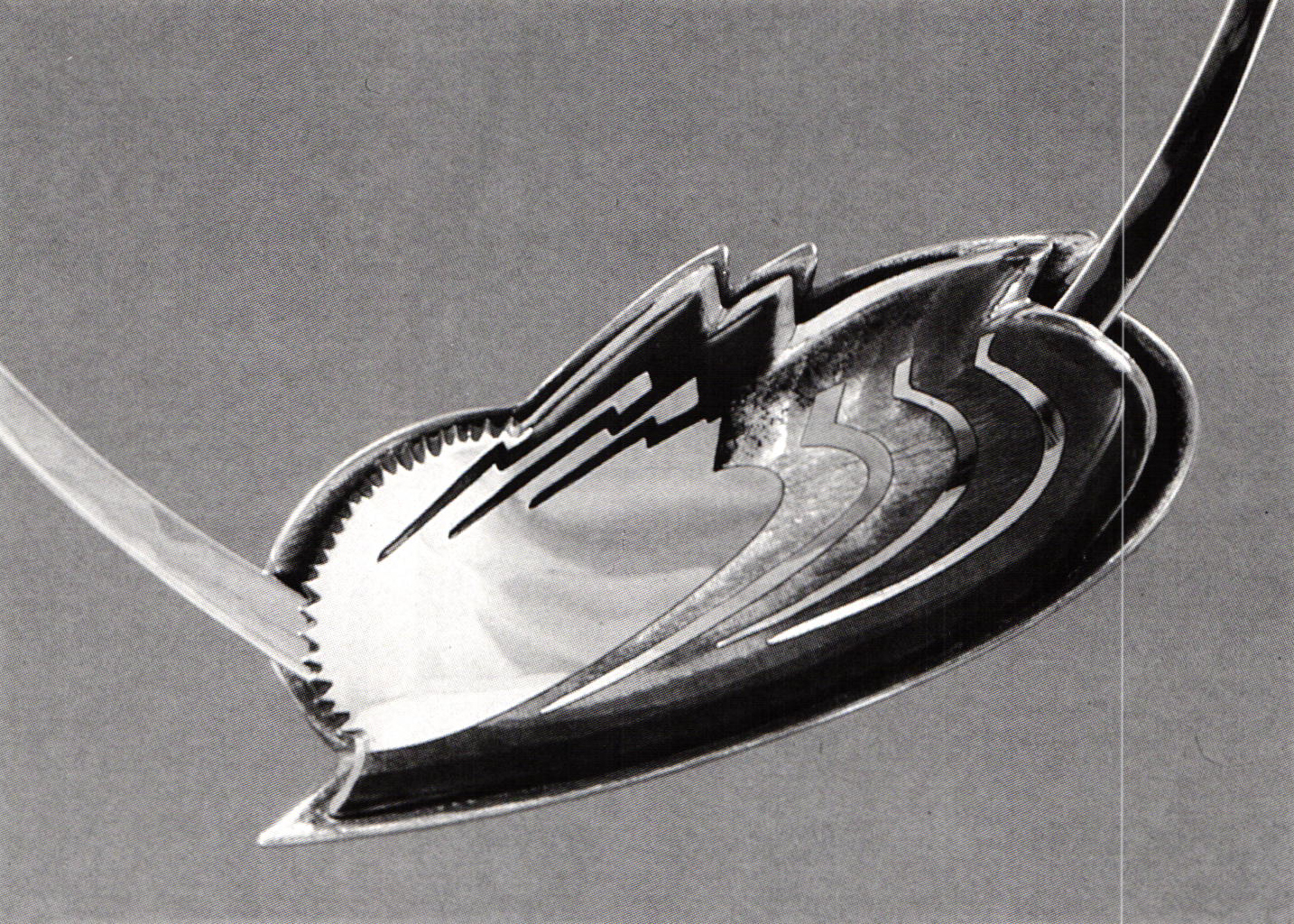

Firing is the most critical stage. It involves a number of principles of chemistry and physics. As the ware enters the furnace, the coating consists of a number of discrete particles. Figure 4 shows the progressive change in one of these particles. First sharp edges become rounded, then as shown in c the particle softens until its weight causes it to sag. With more absorption of heat, the viscosity reduces to the point where surface tension takes over as in d. On any pure metal surface this is a point of equilibrium. Regardless of how high the temperature is raised, or how long the firing continues, the metal surface will be covered with beads of enamel almost spherical in shape and with little, if any, adherence. If the metal oxidizes even the slightest amount, the enamel will wet it and begin to spread as in e. With further absorption of heat, the viscosity reduces further and the enamel spreads as in f. Some readers may argue that certain metals do not oxidize. However, these metals will absorb considerable oxygen from the atmosphere, reducing their surface energy and permitting the enamel to spread.

Adherence of enamel to metal is the result of metal-to-metal bonding between the atoms in the base metal and the proper metallic ions in the enamel. This reaction must meet certain chemical and thermodynamic conditions. The metal ions responsible for adherence are sufficiently near the base metal to be affected by or included in the electron cloud of base metal. Also, they must be an integral part of the glassy phase by virtue of electrostatic forces between themselves and neighboring oxygen ions, which are a part of the glass network. Adherence can be considered to be developed by a monatomic layer of the metal ions that are in equilibrium with both the metal and the enamel. Some oxide must be formed on the metal during firing but no more than the enamel will take into solution. When the oxide is taken into solution, it will affect the color of transparent, frequently resulting in undesirable colors.

Practically all metals can be coated with enamel. This does not mean an enamel can be selected at random, that every desired property will be achievable or that a random firing temperature can be used for any metal. The enamel and the technique should be carefully selected for each metal, based on the following properties of the metal:

- Melting point

- Oxidation characteristics

- Coefficient of expansion

- Tendency to absorb and give off gasses when heated to enameling temperature

- Porosity

Space does not permit a detailed discussion of the various techniques used to achieve the desired results when coating specific metals. As a general guide, select enamels with approximately the following properties as a starting point competent enamel manufacturers can supply this information for their enamels. For gold, copper, gilders metal, iron and silver-plated steel, use an enamel having a cubic expansion of 260-330×10-7 cm per cm per degree C and a firing range of 1350-1500°F. For silver, use an expansion of 300-420×10-7 and a firing range of 1050-1150°F. For 400 series stainless steel, use an expansion of 225-275×10-7 with a firing range of 1350-1500°F. For 300 series stainless steel, use an expansion of 330×10-7 or more with a firing range of either 1500-1800°F or 1050-1150°F. For platinum or titanium, use an expansion of 200-250×10-7 with a firing range of 1500-1800°F.

We are indeed fortunate that some individual put glass on metal more than 3000 years ago. Today, an engineer reading a handbook and comparing the properties of glass, a brittle material, and the properties of metal, a ductile material, might not attempt to combine the two to form a composite.

Woodrow W. Carpenter is Chairman of the Board of The Ceramic Coating Company, Newport, Kentucky.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.