Novorit: Colorful Imagery

2 Minute Read

The Novorit polyceramics system has been on the market for a year and offers fascinating possibilities for the creative color design of individual items and large batches of individual items and large batches of items. Now, with the expansion of Novorit, even photos, graphics and drawings can be applied permanently to items of jewelry and watches.

Apply Novorit Link and Bond

Expose Novorit Bond with TwinLux

With the new Novorit ST system developed by Invicon chemical solutions and marketed by Heimerle + Meule, both companies have set another innovative milestone. This has been made possible through so-called sublimation technology. In general, this means that a solid substance is converted directly into a gaseous aggregate state by heating it. The liquid state is practically bypassed. This process comprises a range of advantages and has previously been used in designing textiles and polyester-coated surfaces.

The sublimation ink involves embedding special color pigments incorporated into a fluid matrix, they are then applied onto a film in any design as part of this new process. The design is then transferred from the film onto objects or textiles at a temperature of 160°C. The transferred color pigments initially penetrate in a gaseous state and then cool off to form a solid state again.

This innovation will be sensational for jewelry makers, offering completely new possibilities for designing creative and high quality treasures with the new modified Novorit substance, which is classified with the additional designation of ST. The basis of the product is a three-dimensional network of methacrylate composite material. In the case of the ST version, this basic component is modified so that the 3D methacrylate expands upon heating (160°C). The gaseous color pigments from the sublimation film are not only applied to the surface, they completely penetrate into the material. During the subsequent cooling phase, the color pigments become solid again and the Novorit ST carrier material contracts. The color pigments which have penetrated into the material are securely fixed. The result: this print-like design and the Novorit ST carrier material fuse to become one.

Harden in CreaStation with heat and pressure

Remove hardened Novorit ST basic body

Sublimation press and film

Sublimation film and Novorit ST

Place film and body together

Separate film and body

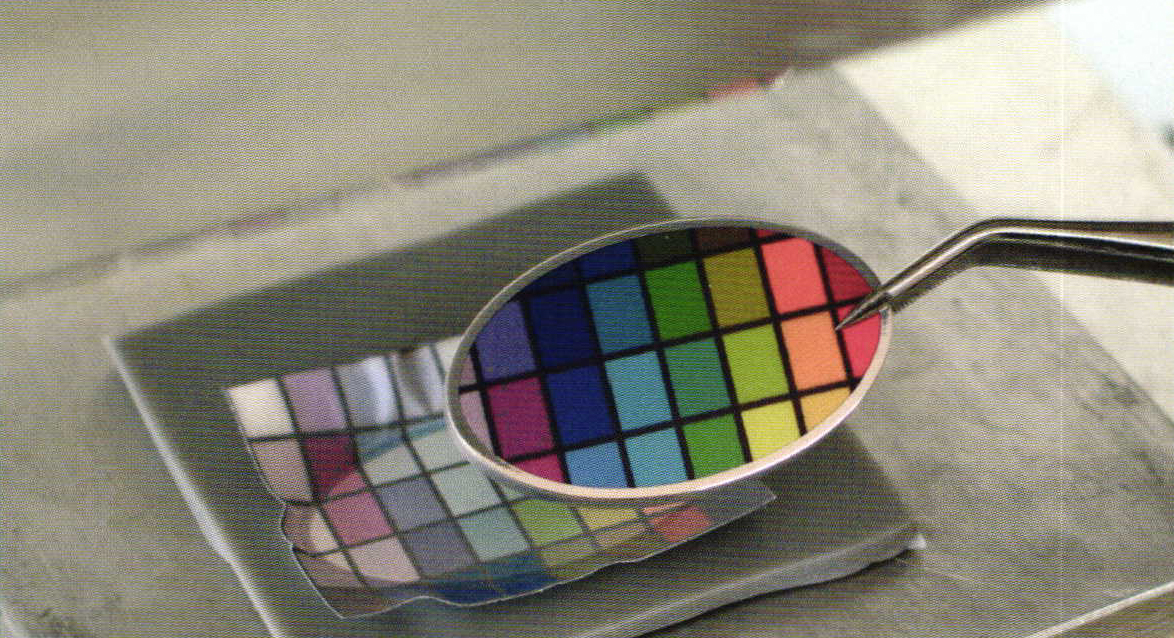

The result: bright colors, accurately transferred

This process opens up completely new design options as well as setting new quality levels and introducing new processing procedures, particularly in terms of industrial standards.

This sublimation technology, along with the Novorit ST, offers various advantages: for jewelry designers, the new system offers strong new color effects meaning that their work can be expressed in new ways by applying their images and graphics. The result are uniform hard surfaces which are resistant up to a temperature of 200°C and have a high level of UV color stability. This technology enables efficient production procedures for individual and mass production with a high level of process reliability. The short production times and low item production costs are also very appealing.

by Axel Henselder

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.