Gemstone Guide

1 Minute Read

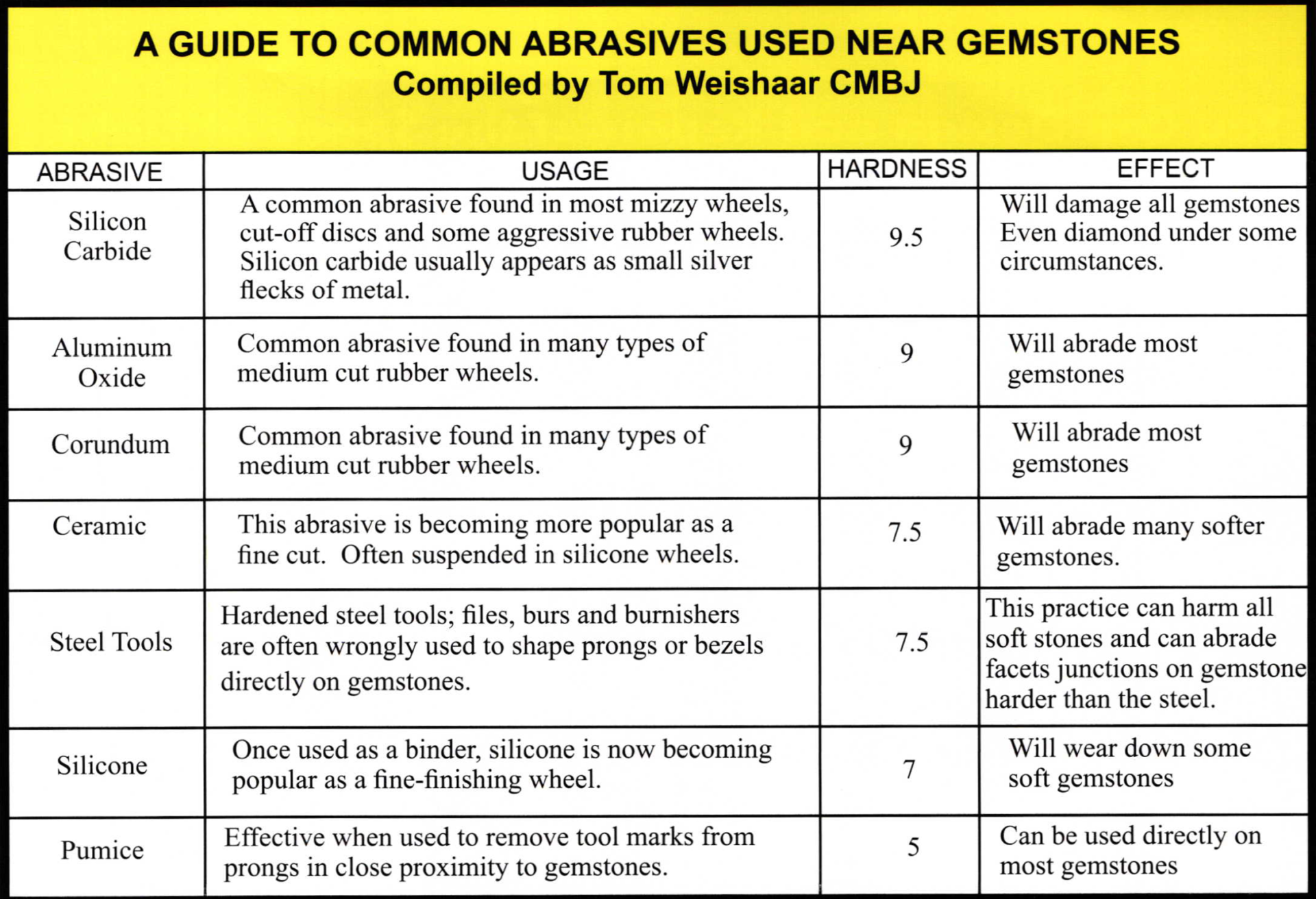

This page contains a gemstone guide to common abrasives used near gemstones; their usage, hardness rate and effects compiled by Tom Weishaa CMBJ.

Abrasive

Silicon Carbide

- Usage - A common abrasive found in most mizzy wheels, cut-off discs and some aggressive rubber wheels. Silicon carbide usually appears as small silver flecks of metal.

- Hardness - 9.5

- Effect - Will damage all gemstones. Even diamond under some circumstances.

Aluminum Oxide

- Usage - Common abrasive found in many types of medium cut rubber wheels

- Hardness - 9

- Effect - Will abrade most gemstones

Corundum

- Usage - Common abrasive found in many types of medium cut rubber wheels.

- Hardness - 9

- Effect - Will abrade most gemstones

Ceramic

- Usage - This abrasive is becoming more popular as a fine cut. Often suspended in silicone wheels.

- Hardness - 7.5

- Effect - Will abrade many softer gemstones

Steel Tools

- Usage - Hardened steel tools; files, burs and burnishers are often wrongly used to shape prongs or bezels directly on gemstones.

- Hardness - 7.5

- Effect - This practice can harm all soft stones and can abrade facets junctions on gemstone harder than the steel.

Silicone

- Usage - Once used as a binder, silicone is now becoming popular as a fine-finishing wheel.

- Hardness - 7

- Effect - Will wear down some soft gemstones

Pumice

- Usage - Effective when used to remove tool marks from prongs in close proximity to gemstones.

- Hardness - 5

- Effect - Can be used directly on most gemstones

Click on image to enlarge:

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.