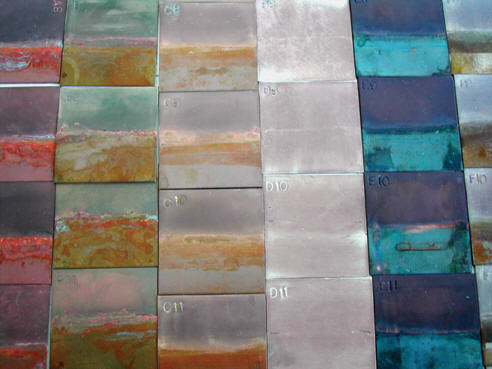

Testing Japanese Patina Solutions

It is important to understand that many variables will affect patina results. Our tests were made on smooth, rolled metal. Textures will change the color, and cast metal has a different structure that can also influence color. These samples include no solder, and because solder is a different alloy, it will react to the solutions differently. Changes in temperature, length of exposure, climate, and strength of the chemicals wilt all influence colors.

2 Minute Read

In an effort to insure that nothing was lost or confused in translation, the formulas given here were tested on a wide range of alloys. These pages show some of our results.

It is important to understand that many variables will affect patina results. Our tests were made on smooth, rolled metal. Textures will change the color, and cast metal has a different structure that can also influence color. These samples include no solder, and because solder is a different alloy, it will react to the solutions differently. Changes in temperature, length of exposure, climate, and strength of the chemicals wilt all influence colors.

Experiments like this are the best way to develop an understanding of the solutions that will prepare you to apply the patinas on your finished work. We recommend making tests on small pieces like this before you mix up large quantities of patina solutions or devote a lot of time coloring a large piece.

Purchase your own copy of "Japanese Patinas" today. |

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.