Modifying Beading Tools

1 Minute Read

Modifying beading tools for clean re-tipping jobs

A colleague recently asked for my help in finding cup burs that were smaller than 008 size (0.8 mm diameter) because he had a micro-pavé re-tipping job for one of his clients. However, commercial cup bur makers stop at 0.8 mm, leaving anyone in need of something smaller on their own.

Luckily, I just happened to know a trick.

When re-tipping, you usually use a laser welder to add material to the tips. But that results in a bit of a blob shaped tip that needs to be shaped into a bead to hold the stone. You can use a standard beading tool to create the bead shape, but it will create flashing—extra metal around the bead that will need to be removed.

Traditionally this material is taken off with a graver, and that works well with larger beads where the flashing is usually better defined and can be quickly flicked off with the graver. But when you're re-tipping micro-pavé, the flashing is pushed down hard and usually extends all the way around the bead, making it a pain to cut loose with a graver.

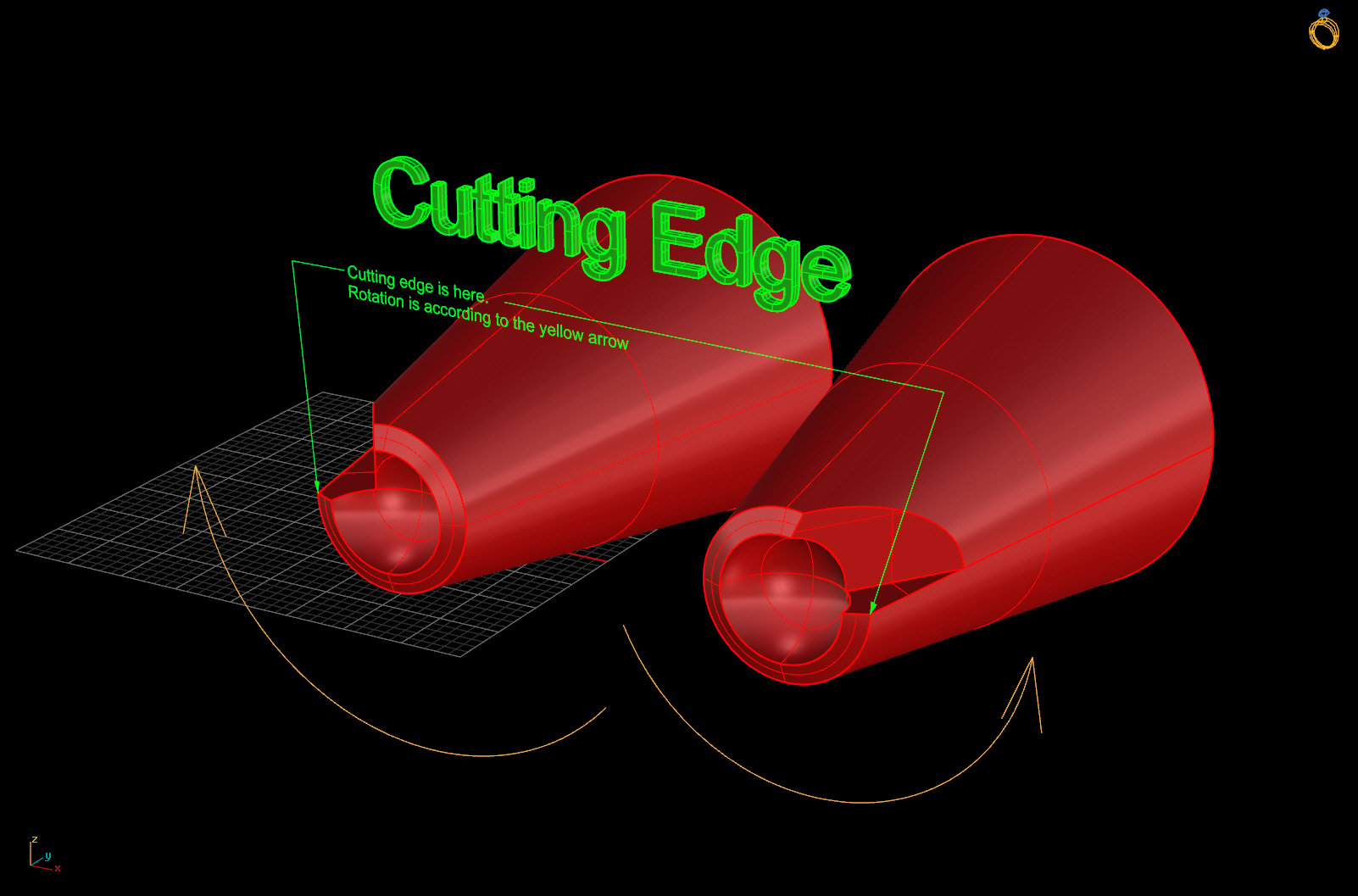

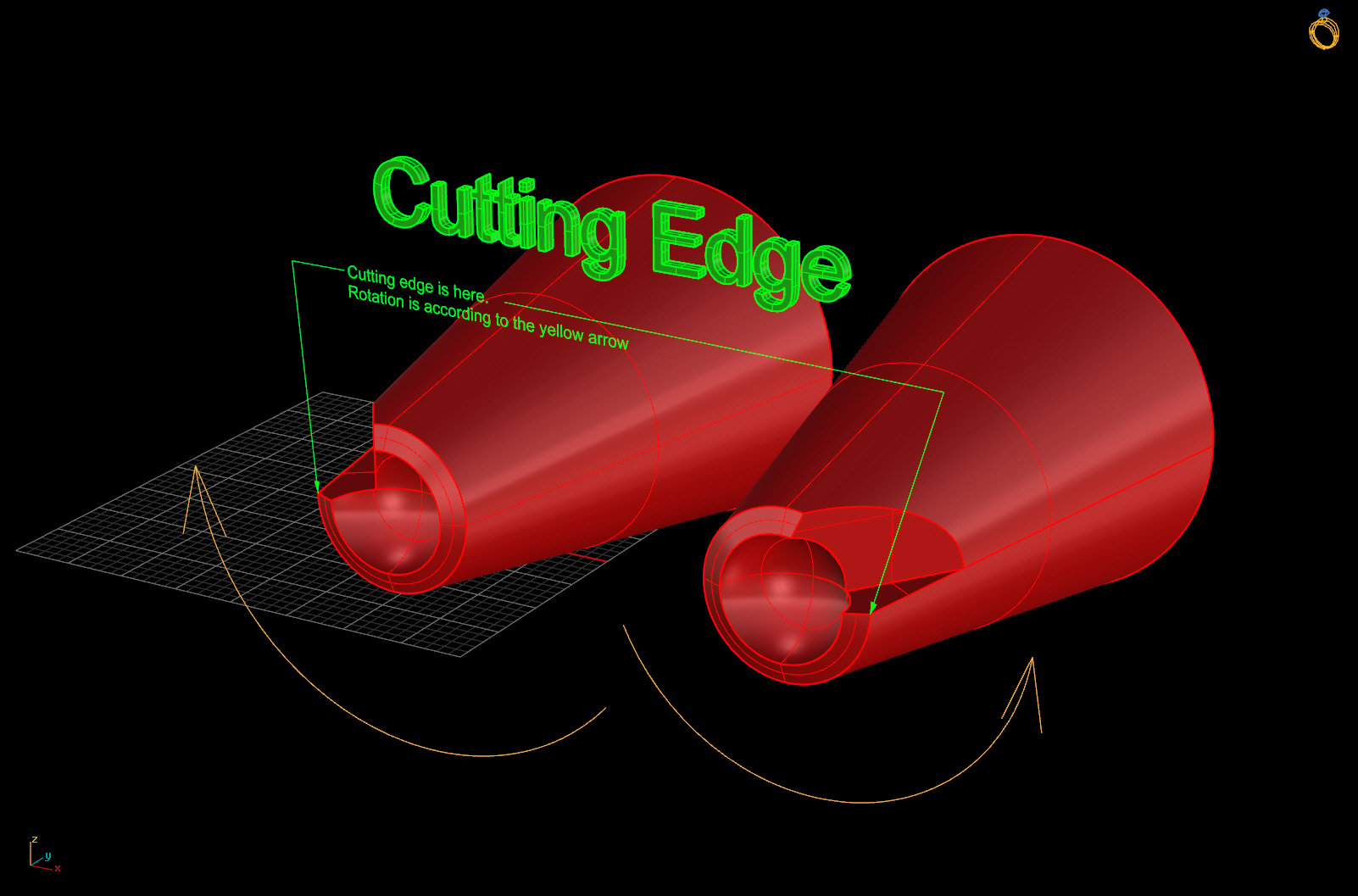

There's an easy and fast modification you can make that will let you make quick work of any bead flashing. Take a very sharp-edged diamond file and make a notch in the end of a beading tool that is the same size as the tool used to form the bead. The notch will work like a concave, single-edge end mill. One side of the notch should go from the edge of the beading tool and follow a radius line toward the center. This creates a cutting edge that is a right angle to the direction you are turning.

Although you can turn the tool in whatever direction you want, I recommend setting the tool up to cut clockwise if you're right-handed or counter-clockwise if you're left-handed. To create the notch for cutting clockwise, remove metal to the right side of the radius; to cut counter-clockwise, remove material from the left side of the radius.

Now, with just a couple of rotations of the modified beading tool, you'll be able to cut the flashing off of beads in a flash.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Related Articles

How to Customize Short Insulated Tweezers

Overcoming Tool Limitations

Customized Ultrasonic Sediment Bucket

Half-Ground Round Bur

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.