Manufacturing Jewelry in Platinum Some Basic Facts

4 Minute Read

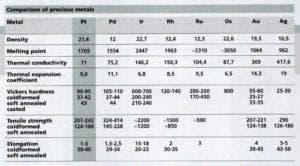

Properties of platinum

- To get one ounze of pure platinum you have to process 11 tons of ore.

- Platinum (Pt) is one of the heaviest precious metals.

- Pt has an extremely low thermal conductivity, it doesn't bend or twist even under the effect of heat.

- Platinum doesn't tarnish or oxidise on air.

- Pt has a very good wear restistance.

- It can disolve only in hot aqua regia.

- Pt has catalytic properties. It's always needed to start chemical processes, without participating in this process.

- Pt and platinum group metals are the only material for the production of glasfibres and melting crucibles for glass.

- Regarding on high melting point and resistance to attack, Pt is famous for the measurement of high temperatures.

- Pt has an excellent skin compatibility.

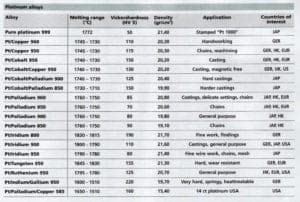

Platinum casting

- The weight of platinum castings will be about 30% higher than for 18 karat gold.

- The weight of casting trees are between 100-3000 gr, in average 300 gr.

- Different tree and sprue design, regarding on total different feeding behaviour.

- Centrifugal spin-casting machine required, torch or induction melting. Ultraviolet lenses for melting platinum is recommended.

- Special investment (phosphat or acid based investment) required.

- High preheat temperature, up to 1000°C necessary. Special heat resistante flask required.

- Oxidation and gas resistance of platinum is extremly good.

Casting

- Even 100% scrap can be melted.

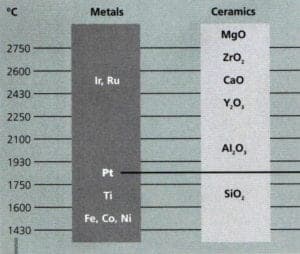

- Special crucibles made of calcium or magnesium stabilized zirconia required.

- Casting process allows no waiting time, melted platinum has to be poured quickly.

- Rapid loss of heat during the casting process.

- Use hydrofloric acid to dissolve the platinum investment from the cast product.

Handworking

- Use a separat tooling kit for Pt, and keep them clean.

- Avoid any contamination during the manufacturing process, work clean.

- Use rolls and dies (tungsten carbide) highly polished.

- Pt tends to smear or drag wear on working tools.

- Pt can be extensivly deformed, without becoming brittle. Most platinum alloys allow coldwork 80% and more.

- Reduction less than 30% should be avoided.

- General annealing temperature is about 1000°C, a stress relieve at about 600°C is possible. (Guideline: for each mm thickness, heat min. 1 minute, bright orange heat)

- Annealing with a torch: use a broad flame and heat up to a dull red.

- Binary Pt alloys don't age harden, so quenching is not necessary.

- Metal contaminations of Pt surfaces has to be removed by pickling in hot 10% nitric acid.

- Iron contaminations can be removed with hydrochloric acid.

- Pt/Co oxides can be removed with hot hydrochloric acid 20%.

- To enamel Pt is not possible, only Pt/Pd with limited special colors.

- Pt doesn't tarnish or oxidise on air.

- Regarding on elasticity Pt is ideal for settings. Pt bends easily and does not spring back.

- Tension settings are speciality for Platinum.

- Always polish the setting, before you cut the seat for a stone.

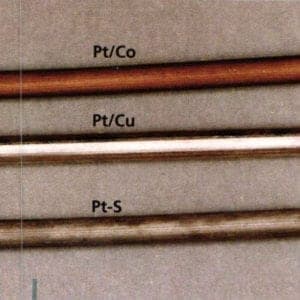

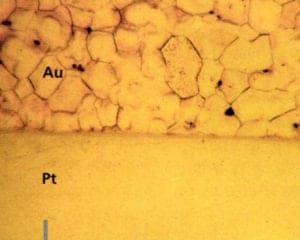

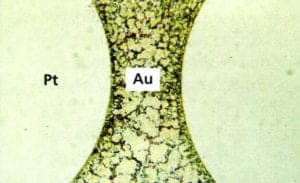

- Color combinations are easy to produce.

- Etching of gold inlays are easy to produce.

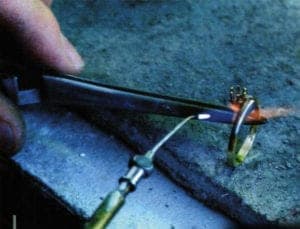

Joining techniques

- Useful joining techniques for platinum are: Fusion welding, pressure welding, spot welding, laser welding, soldering, sintering, bi metal casting, puddeling, mechanical processes.

- Principle: welding is better than soldering, solder seams to be polished out easier and are visible, they don't match the colour.

- Before joining operation, clean Pt in an ultrasonic cleaner to remove oil, grease and metallic residues.

- During welding/soldering you may not need a flux.

- If you weld, use a filler of the same alloy.

- The wettability between Pt and solders are excellent.

- Use a heat source with less carbon, like hydrogen/oxygen.

- Pt has a relatively low thermal diffusivity, the heat stays near the working area.

- Regarding on the low heat conductivity it is possible to repair without damaging stones.

- Use a ceramic (alumina) brazing pad, no charcoal blocks.

- Don't use iron binding wire and dirty steel clips, this will contamine the Pt.

- Use tungsten twisters and tungsten solder picks to place solder on hot platinum.

- To bond Pt with gold there are special fluxes (free of borates) available.

- Use welding lenses when brazing or welding Pt.

Finishing

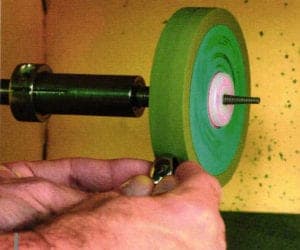

- No short cuts for filling and polishing

- Choose the minimum grade of abrasive that totally remove the deepest defects.

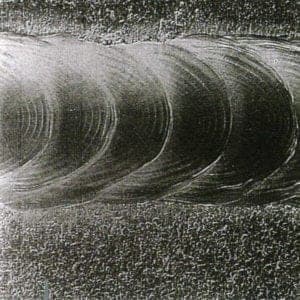

- Emery/polish across line defects or solder seams to reduce dragout.

- Change always the working direction at 90° to the previous direction.

- Frequently use fresh abrasive surfaces Avoid the transfer of coarser particles to the next finer process. Good housekeeping is necessary.

- Before surface texturing, prepare a highly polished surface.

- Electrolytical polishing and tumbling are not possible.

- Plating with Rhodium or Pt is recommended, the coating increases the wear resistant and eliminates color differences at the solder seams.

- If Pt will be combined with gold, finish the Pt before you join it to the gold, otherwise the gold will be overpolished, because it will finish faster.

Refining

- Keep Pt fillings and scraps separate from other precious metals.

- Hold platinum/gold combination scrap separate.

- Don't seperate your fillings with a magnet, Pt/Co is magnetic.

- Clean material from sheets, wire etc. and the same alloy can be remelted and used again, without problems.

by Klaus Wiesner