Customized 3 Jaw Chuck & Earring Holder

3 Minute Read

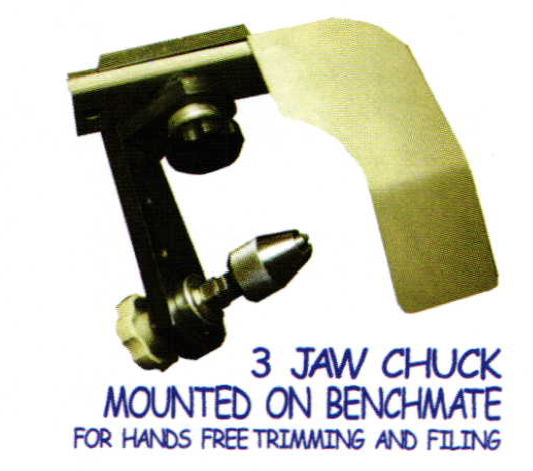

Steve Satow shares his procedure for customized 3 Jaw Chuck to mount on a Benchmate for hands free trimming & earring holder.

In this view you see the chuck in its package from Harbor Freight. I like this chuck because it opens without a chuck key for those jobs that don't require super tight jaws. It's priced at less that $5.00. The whole project costs less than $ 20.00.

In the above photo you find the jaw unpacked and the two nuts needed to modify the base. The stem mounted into the base of the jaw will unscrew and is standard 1/4 inch thread so you need a 1/4 inch thread nut and a 3/8 inch fine thread nut. Not pictured is the extra bearing and a 3/8 in. compression washer you will need to order. Use GRS item number 002-510 at phone number 1-800-835-3519.

In this view we have removed the screw on the base of the chuck. Then screw the 1/4 inch nut all the way down the shaft until it's tight against the unthreaded part of the shaft. Then mark the base screw and remove the nut and cut it off there.

In this view you see where we have filed the end burs off where we cut the 1/4 inch base screw off.

If you don't have a laser, screw the nut onto the end of the screw until it's even with the end and then braze the nut onto the end of the 1/4 inch shaft. Then center the 3/8 inch nut on top of the 1/4 inch nut and braze them together. If you have a laser, screw the 1/4 inch nut onto the shaft until the end is even with the nut. Laser the end of the shaft to the nut. Then tighten it into the base of the chuck. Center the 3/8 inch fine thread nut on top of the 1/4 inch nut and weld it securely to the 1/4 inch nut.

In this view you see the chuck mounted on to the Benchmate arm ready to securely hold small round objects to be filed, ground or drilled. You use the plastic headed 3/8 inch fine thread bolt that holds the collar of the Benchmate on. Put the compression washer and one bearing on one side of the arm. Then the other bearing with another compression washer against the 3/8 inch nut welded to the shaft attached to the chuck's base. When you mount this to the arm use a wrench to hold the 3/8 inch nut as you tighten the hand knob. Once it's snug you can spin the whole unit with the handle without it loosening up as you use the chuck.

I like to use this to hold stones set in straight bezels that need the bezels cut down where the culet is exposed. This is something you can't do by just draw sanding or filing the bottom or you will damage the culet.

It is also a nice holder if you have to file the bottom of a straight bezel so it will fit a domed band.

Earring Holder

This idea is from an idea Jurgen Maerz of Platinum Guild International suggested for holding rings. I scaled it down for earrings. Start with 2 new corks and 2 solid brass hooks from the hardware store. Polish the hooks and plate them with copper, gold, and then rhodium so they won't corrode as quickly.

Screw them into the center of the bottoms of the corks,

Bend a pair of hooks shaped like this and make the top hole big enough to fit the hooks on the corks. Then gold and rhodium plate the hooks.

The hooks should fit loose like in the picture.

This view shows the hooks with empty earrings on them, ready for the ultrasonic.

This shows the earrings held with the steaming tweezers. The earrings can be steamed without them blowing off the hooks. Then they are ready to be rhodium plated still on the hooks. Then back to the steaming tweezers for a quick burst of steam and they are done. No more fishing them off the bottom of the ultrasonic and having to re-polish them.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.