Cross-Sectional Critique

2 Minute Read

This article is a Cross-Sectional Critique of applying clipping planes to model manufacturability written by Darla Alvarez of GIA Jewelry Design & Technology Instructor.

One of the potentially overlooked advantages of using CAD for jewelry design is the ability to examine a piece for manufacturing issues well before prototyping. By dissecting a model prior to 3-D printing or milling, various defects can be caught and rectified before any tangible are used. The best way to do this is by using the "Clipping Plane" command, which creates a cross-sectional view. This creates a visual graphic "layer" that makes it possible to assess and measure the viability of the design.

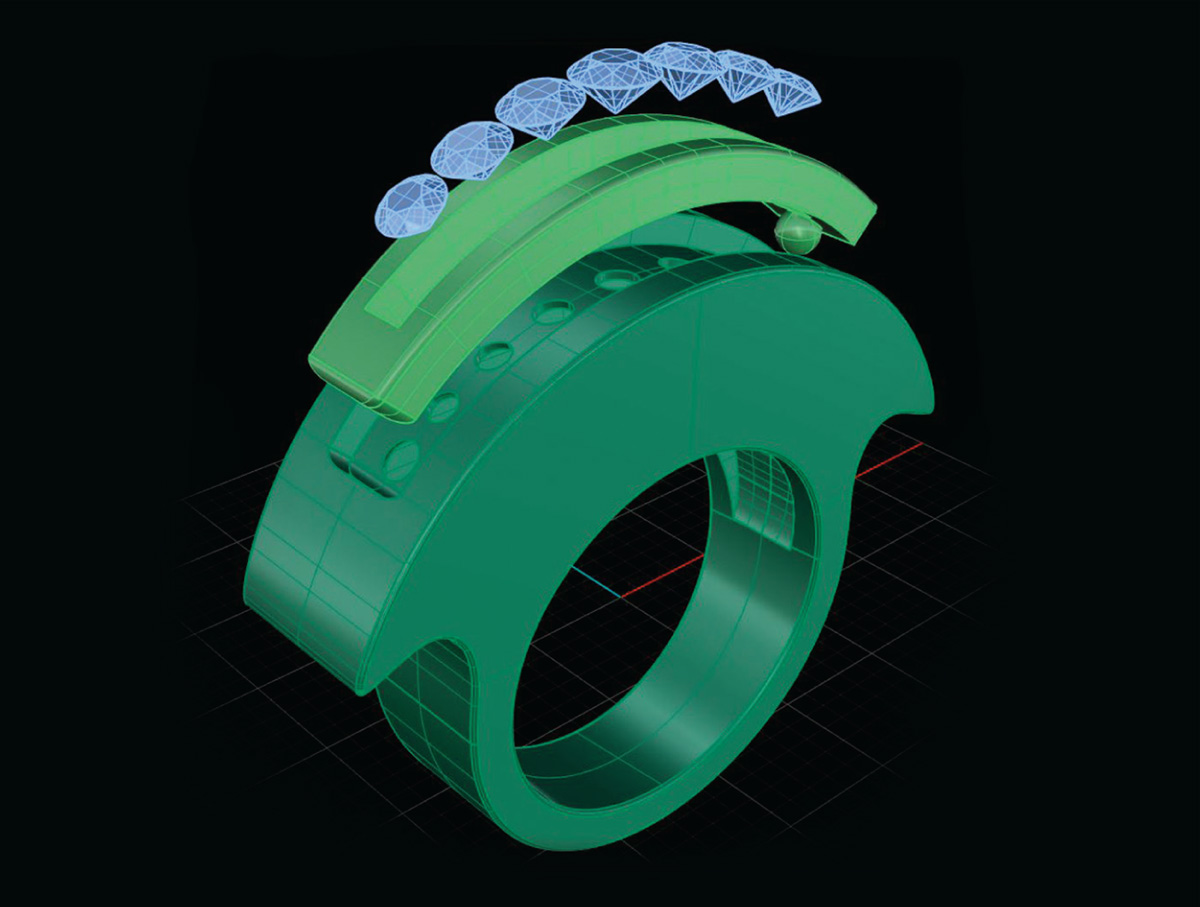

A clipping plane object placed in a build area represents an infinite plane, which is used to slice geometry to give the user cross -section visibility. It slices the object at the point of placement, like cutting through an object with a knife and then looking at the inside. The exploded view of an example model is provided to aid in the following analysis.

- A great start to checking the manufacturing quality of a model is to look for any areas that may create casting issues. Place a clipping plane parallel to the finger hole at the center of the example ring.

In the illustration, the clipping plane is the rectangle with the large "X" crossing through it, bisecting the model. In this instance, the hollow area inside of the ring, which appears by all other examination to be sound, actually creates a thin, sharp area that could very well affect casting. The thin area, which I've marked with an arrow, would fill with investment. That investment, being thin, can break off once metal rushes into the empty cavity at casting and mix with the molten metal, ultimately creating voids in the ring. Adjusting the hollowing by eliminating this thin pocket will fix the problem.

- Another use for a clipping plane is when checking how models with multiple pieces fit together.

In the example ring, an interlocking ball and socket system is used to make assembly easier after casting. A clipping plane placed perpendicular to the ring reveals a problem with the spheres as made. While they fit together fine in CAD, these spheres could not be pushed into place in metal without enlarging the corresponding sockets. In this case, straight pegs or tabs may be more suitable.

Also, other cutouts made for the assembled pieces are measurable. In this ring, the channel support is only 0.37 mm thick and needs to be thicker for structural integrity in both casting and assembly.

- Since CAD already uses virtual stones, a clipping plane is also useful for looking at the relationship between the stones and setting before any real setting begins.

The channel-set stones in this ring, when viewed cross-sectionally, are very close together with a lot of metal covering the stones. The stones would be better farther apart to allow for natural variance in stone size and to ensure the channel is long enough for the setter. Also, the channel is too narrow for the stones to be set, as is shown by the arrows in the perpendicular cross section. Too much metal would have to be removed at setting, which is both wasteful and time-consuming.

These are hardly the only ways to analyze a model for manufacturability with a clipping plane, but checking for casting, assembly, and setting issues are three large areas of consternation when the virtual and the real collide in unexpected ways. CAD tools are not only for creating wearable art, but also for critiquing that art.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.