Bench Mag Favorite Tips 2002

6 Minute Read

This article page is from a section "Favorite Tips" from BENCH Magazine 2002 submitted by readers and BENCH Magazine Staff covering favorite tips on removing and straightening kinks in chains, jewelry cleansing, chain repair and more.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

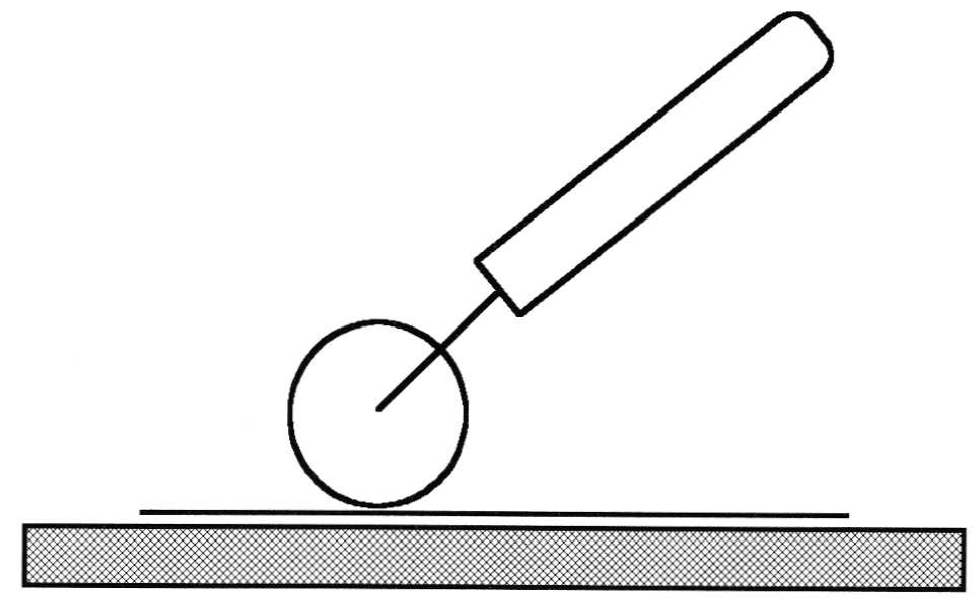

To straighten kinks in flat chains such as herring bone, lay the chain out on a hard surface such as a formic counter top. Then carefully roll across the kink with a wooden wallpaper seam roller.

Another method to use to remove kinks is to carefully squeeze the chain between the jaws of flat nose pliers.

A bad kink maybe removed with the following method. Grasp the chain between your thumb and index finger, placing one hand on each side of the kink. Then slowly rotate your hands in a circular motion in the direction opposite of the chain twist.

An interesting tip I have found when cleaning jewelry with small gemstone is. I use a round coffee grounds plastic container that has the very fine silk screen sections in it. The kind you use in the small coffee makers. I place the piece in the container and the whole container sinks into the ultrasonic. lf you use the right size, its just big enough to get two containers side by side. And lf you wanted to use just one container you could hang other rings and brace- lets off the outside of the container and clean them while you clean the piece with small gemstones. lf any stones happen to come out they are saved in the coffee grounds container and easily recovered - Very quick and very easily. I think easier than the plastic bag suggestion. Thanks for the emails, they are informative keep them coming

- Steve Kaye

Kappy's Fine Jewelry - Lake Worth, FL

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Try Styrofoam instead of cardboard under your polishing motor (Fall Issue page 31). It absorbs more impact…sometimes the piece just sticks where it hit. Don't forget to line the back of the hood, too. The white Styrofoam also reflects light, and makes it easier to see inside the hood while polishing (l like to see EVERY scratch white I'm still at the polisher). I hang a postcard inside the hood, just above the buffing wheel and slightly resting on it. It acts like a mud flap, to keep the dust from coming around with the wheel and flying into my face. I also hang an old 2″ paintbrush next to the polishing hood. When I'm finished, I dust the inside of the hood and all around the motor. I keep my polishing area as clean as a kitchen counter. Keeping this area clean does more than prevent buffs from becoming contaminated. It makes the task of polishing more a part of the creative process, rather than the dirty dungeon I have seen in some shops (YUCK!!!). I also found that the disposable masks that dentists wear are great for keeping my lungs clean, too, and far more comfortable that the hardware store variety.

Too often, polishing is seen as a "necessary evil" to be completed as quickly as possible. I try to devote as much time to careful polishing and finishing as I do to fabrication and stone setting.

- Doug Zaruba

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

To solder closed a link in a hollow link bracelet, take a small section of wire that matches the color and karat of the bracelet link. Use a wire diameter hat will semi-snuggly fit inside the link. Then, place some paste solder in each end of the link and insert the wire. Gently hold the link closed and heat until the solder melts. The wire will provide more surface area for the solder to flow to make a stronger joint.

When soldering hollow link chains or other fine chains do not use a solder pick. The pick will draw heat away from part of the chain causing the remaining chain to melt easily.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Chain Repair

Here's trick for chair repair: - Take a small piece of copper sheet and drill or punch small holes of various sizes in it. Lay your chain to be soldered on a charcoal block, and place the copper sheet over the chain with the link you are soldering visible through a hole in the copper sheet. Use a hole that will allow you to see only the link that you want to solder. When you apply the torch flame, the copper will act as a heat shield to prevent the adjacent links from getting hot. This little jig will make easy work of repairing those extra light micro chains and hollow chains that always seem to come in for repair.

To solder jump rings use sheet or wire solder and clip into small chunks and place on the soldering block. Hold the jump ring in a pair of soldering tweezers with the joint down. Flux the solder snippet, the jump ring, and the attachment point. Melt solder into a ball and pick up with the jump ring as you would with a soldering pick. Heatthe piece until the flux turns liquid and touch the jump ring to the piece. When solder flows remove heat quickly. lt helps to have a good solid rest for your wrist.

- Jerry Holt

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

To keep a chain from tangling in the job envelope, place the chain in small zip-lock bag with its catch sticking out of the top. When removing, hold chain by clasp and lift out of the bag. Do not the open bag and it dump out.

To make soldering jump rings easier you might try this technique: roll out a narrow strip of solder in the rolling mill orcutand pound a strip of solderverythin. Cutthe strip into small snippets. Insert the appropriate size snippet into the seam of the jump ring using tweezers or pliers, (it should be thin enough to not force the join open). Heat the joint until the solder flows. It makes a perfect seam every time, as the solder cannot jump to one side and flow away from the seam. This isn't practical for soldering dozens or hundreds of jump rings at a time, but if you need to control exactly where your solder flows this is a handy alternative to using a solder pick.

- Michael David Sturlin

Scottsdale Arizona

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

A tip for chain making: Fold a piece of copper sheet in half. Then cut a V in the fold. Unfold to where it will stand up on its own, and the V is at the top. Use the V to prop the jump ring up so that the joint is visible and ready to solder. You can use tweezers to move the chain along as you solder. This helps keep from soldering links together. Hope this is helpful to someone.

- Sarah Philbeck

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Avoiding the Frustrated Silver Laser Welders Syndrome

When using a laser welder with silver use silver solder sheets and cut thin strips to use as welding rods. By using silver solder you don't need to use a magic marker to keep the silver from ricocheting, it's less messy, you get a good solder joint and you are able to do most any silver solder job that maybe impossible with traditional methods (inlaid' enamel, etc.). By using the silver solder strips instead of silver wire you can easily use this technique on any silver jobs (jump rings, spring rings, sizing) and any jobs where soft solder may have been used. It also makes gold filled glasses stronger and more pliable than using gold. Settings always vary, but a good starting place using this method is 280v/3.5ms/50 beam.

- Tim Dickens

Herteen and Stocker Jewelers

lowa City IA

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.