Basic Milling Technique

3 Minute Read

In working on jewelry there are many tasks that seem simple - you just do it and don't think about techniques. Milling is a prime example. You stick a bur in your flex-shaft, step on the pedal, and away you go. However, as simple as cutting with a bur seems, there are techniques to use that will improve the efficiency of cutting and avoid waste in the shop.

Proper milling techniques allows; Smoother Cutting, resulting in less cleanup; Accurate Cutting, resulting in higher quality work; and Longer Tool Life, resulting in saving money.

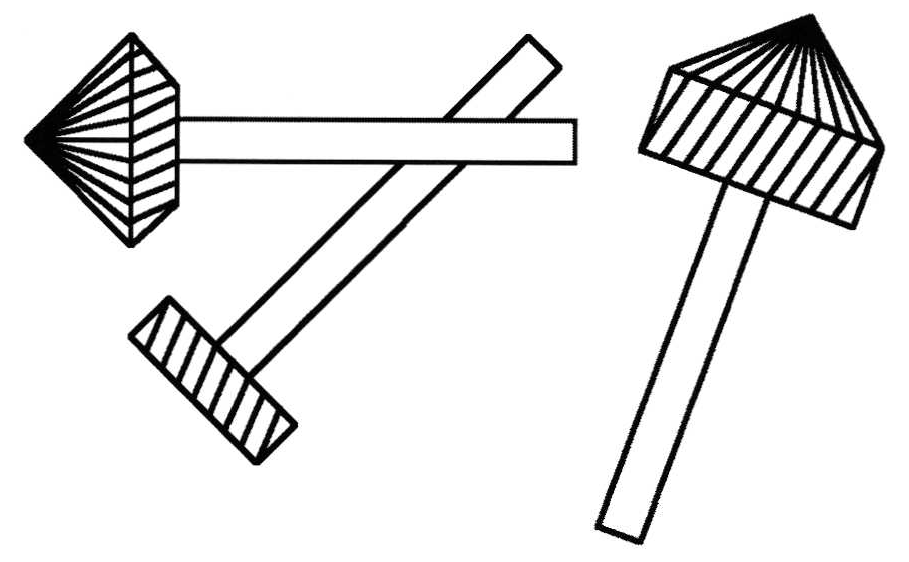

Burs are used for a variety oftasks. They can be used for functional or merely decorative task. Functional usage items include cutting notches in prongs or channels in plates for stone setting. Decorative uses include creating surface textures or decorative patterns.

A quick look through a jewelry tool catalog will reveal that a variety of shapes and sizes of burs are available. A well-equipped jeweler's bench has an ample supply ofthese.

In jewelry work, the piece of jewelry is generally held steady and the bur is move free hand over the jewelry. Because in all milling actions metal is removed, the chips should be gathered and save for reclaiming. Always wear safety glasses when using a bur, to protect your eyes.

To achieve the best results the following procedures should be followed:

- All cutting tools must be kept sharp. Dull cutting edges are dangerous to use as they have a tendency to slip off the metal rather than bite into it. Burs that slip can cut or pierce your fingers. Dull cutting edges take longer to perform the work, resulting in lower productivity. They cause excessive heat buildup that could damage some jewelry or the tools themselves. Dull cutting edges produce poorer quality work. They leave more burs on the metal rather than cutting cleanly. In addition, they do not always cut true, resulting in off centered holes, and uneven or untrue cutting

- Keep the cutting edge cool, at least within an acceptable temperature range. To do this, always use a lubricant while using your burs and drills. You can use oil based or solid wax-based cutting lubricant. This helps keep the cuffing edges cool prolonging tool life. In addition, it helps the metal chips flow away from the cutting edge preventing the teeth from clogging.

- Use a steady, slow to medium speed. Flex-shafts can operate at speeds up to 14,000 {pm, some even faster. Burs and drills (with the exception of carbide and diamond tipped burs) should not approach this speed while cutting metal. You should operate the flex-shaft at no more than medium speed, and The Larger The Bur The Slower The Speed. High Speed burs are a description of the type of steel used and not indicative ofthe speed used to operate.

- Use light even pressure. Excessive pressure to vigorously cut metal will over heat the burs. This heat will remove the temper from the tool and it will no longer be able to keep a sharp cutting edge. Let the tool do the work. Do Not Use Excessive Speed Or Pressure To Force A DullBur.

- Insert the shank all the way into the hand piece. The chuck should hold the shank as close to the bur head as possible. This will provide more accurate control and is safer to operate.

- Always use a steady speed and even pressure. Varying the speed by pumping the foot pedal or uneven pressure while cutting will cause uneven cutting and wear out the flex-shaft prematurely.

Ganoksin Staff Note: Finding The Best Flex Shaft Tools & Accessories

Don't miss our expert buying guide to the best rotary tools, including flex shafts and accessories! Find it here.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.