Metalsmithing 101: Introduction to Metalsmithing

Article: Jewelers Saws: Blade Sizes and How To Choose Correctly For Your Projects

Originally published under the title: Selecting the Correct Saw Blade

This article provides and describes useful tips for selecting the correct saw blade by Alan Revere including some important things to consider for blade selection.

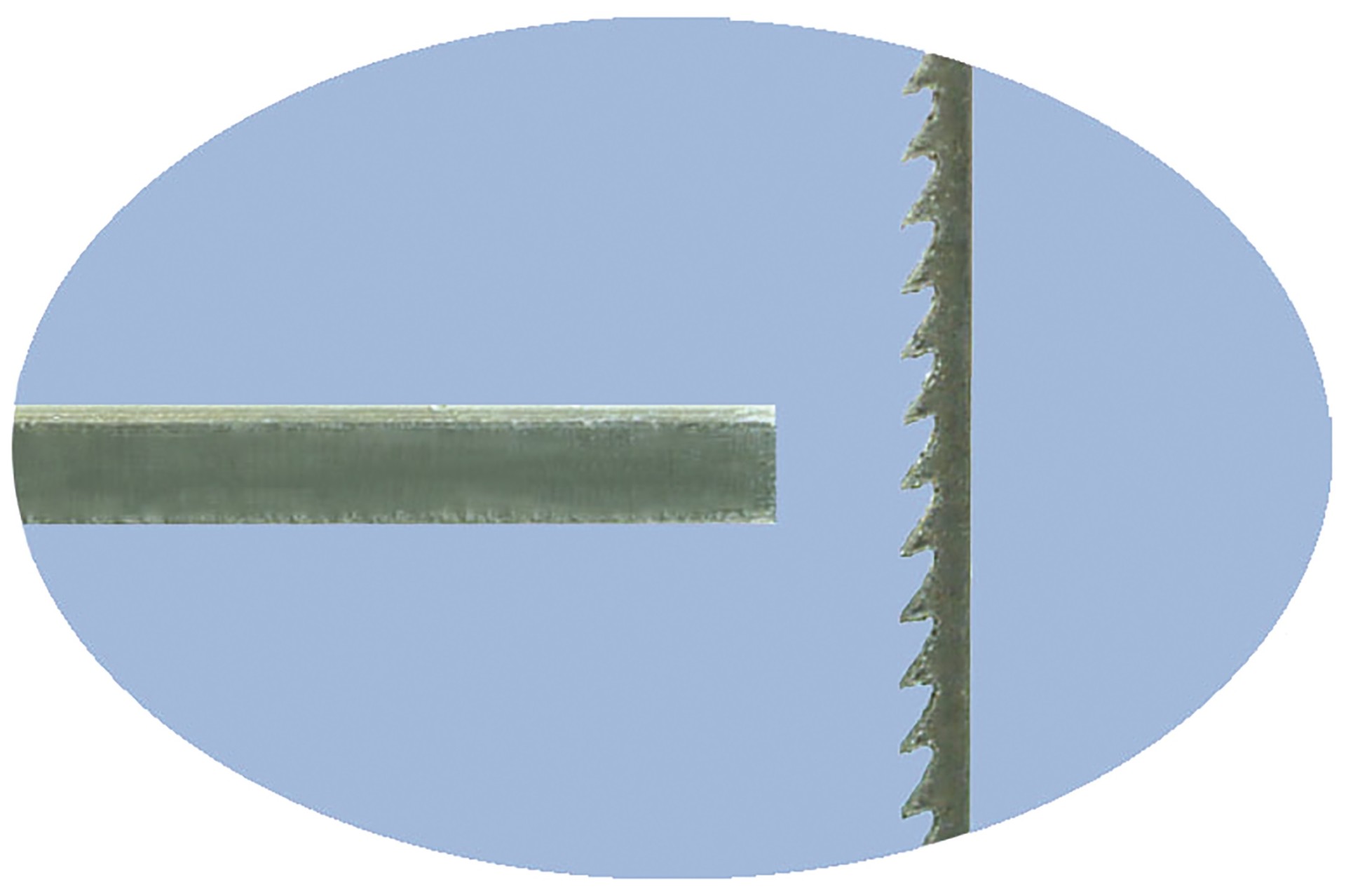

Sawing is a fast and easy way to cut and separate a piece of metal into two (or more) parts. The goal of sawing is to use the hard steel teeth of a blade to chip away a groove in a softer metal. This is accomplished by the row of little chisel tips, or teeth, that chip away tiny particles from the metal sheet.

The Best Jewelers Saw Blades By Size

Buy List

One of the most important parts of sawing metal is selecting the correct size blade for the job at hand. Saw blades come in a range of cuts, depending on the distance between the teeth, or teeth per inch. Jewelry tool suppliers offer blades ranging from the finest, #8/0, then #7/0, #6/0, etc., to 0 and larger blades (#1, #2, and beyond for the largest sizes). Finer blades are easier to use, but slower. Coarser blades cut faster but remove a wider path. The best guideline for deciding on blade thickness is to choose a saw blade with two or more teeth for the thickness of the metal being sawed. If you use a coarser blade with fewer teeth, it will bind and be difficult to use.

In addition, it's important to remember to lubricate your blade frequently, use the whole length of the blade when sawing, and guide the blade forward with very light pressure. And if you are sawing a long straight line, tilt the blade forward for better alignment.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.