Soldering, Brazing and Welding edited by Bernard E. Jones, 1916

This 1916 book (republished in 1921) teaches the core skills of soft and hard soldering (brazing) and introduces basic principles of welding metals. It is a book derived from many articles by different authors in the magazine ‘Work’, an illustrated weekly of the time. Oxy-acetylene was a new process at this time and this kind of brazing with brass, and welding metals other than steel were new possibilities for metal workers.

The excellent descriptions, definitions and pictures are very clear and understandable. There are some really interesting recipes and divisions of types of soft soldering. The section on soft soldering has way more information than any current book on the subject. The detail and images is very good.

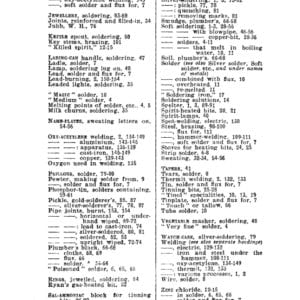

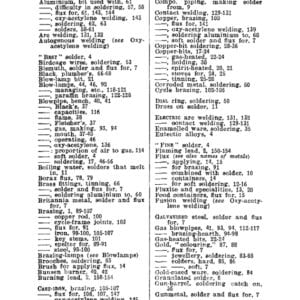

There are for example recipes for lead/tin solder for aluminum and other oddities as well as fluxes for different metals. There are some odd terms, “Killed Spirit” for instance is called zinc chloride today. And ‘rottenstone’ is what we call Tripoli. Methods of using paper cones to pour solder into water to make wire are described. There are a number of solder recipes that melt in boiling water. There are some very interesting and complex soldering iron shapes for soft soldering work. Tinning methods are dealt with. Aluminum soldering and solder recipes are covered.

There is some excellent information on mouth blowpipes (still the commonest ‘torch’ if you go on sheer numbers being used worldwide). I’ve never seen some of the designs pictured. Thorough instructions for how to build bench torches, blowlamps and heating devices are in several chapters in the book. These instructions are unique in any book. Gasoline, kerosene and other types of torches and their maintenance are described.

Hard soldering is well covered with a number of recipes for silver solders. There are lots of details on making hard silver solders, and proper heating methods. Gold solder recipes are listed and gold soldering dealt with well.

There is a large chapter on using ‘spelter’, that is brass powdered as brazing alloy mixed with borax flux to join steel, copper, brass, even cast iron. More information on making torches and a ‘brazing pot’ is included (Mind you there was a lot of asbestos used back then, we would use other materials today). Brazing tips include wire brushing superfluous brazing material off the top of a joint while it is still hot in order to save filing and cleanup time.

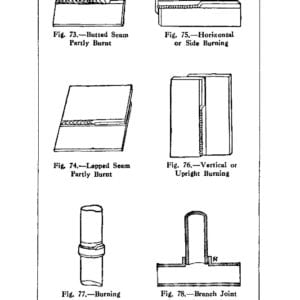

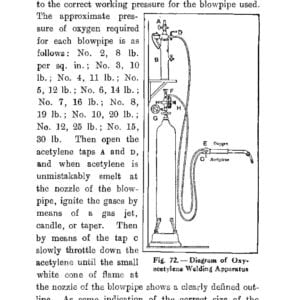

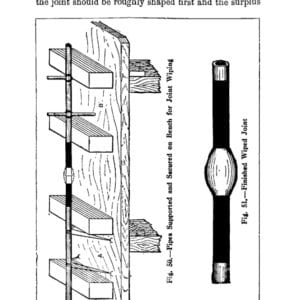

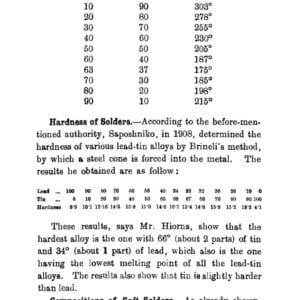

There is a chapter on forge welding iron and steel. Electric welding and thermite welding (with recipes) are addressed. There are even instructions on how to cast iron into sand molds by burning out a wax model with thermite, again something I have never seen described. Oxy-acetylene welding for steel, iron, cast iron, aluminum and copper is detailed: it is surprising how similar the equipment is to today, though many welders then apparently generated their own acetylene at the welding site. Flux recipes for all the metals are detailed. Lead ‘burning’ or welding to make homogenous tanks and surfaces for chemical and architectural use is dealt with.

An interesting and good book.

File Size: 9.82MB, 166 pages. Many illustrations