The Art of Hard Soldering By Henry G. Abbott, 1895

This 1895 book is very good. It describes the issues and techniques used in hard (and to some degree in soft) soldering. It is 74 pages of distilled, bright information.

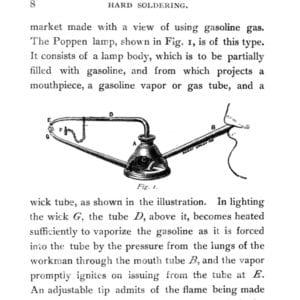

There are a number of mouth driven blowpipe torches described using various fuels. Alcohol and gasoline are recommended. Gasoline torches of various kinds are described with very clear engraved illustrations. (Gasoline torches are still standard in many tropical countries mostly ones with open sides to their workshops lots of air blowing through). The beginnings of gas torches are shown, and it makes one realize how far we have come and at the same time lets you understand the principles behind today’s torches. Odd arrangements of tubes and heating systems for pre-heating the gasses are used to get the temperature high enough to melt platinum.

Mouth blown systems were extensively used, and tips for using them include rubber mouthpieces and gold plating any parts in contact with the mouth. A coiled tip preheated the air being blown into a flame and this doubled the heating power of a standard blow-pipe.

The foot bellows shown to supply oxygen to a flame is exactly the same as I learned to use in the 80’s in Germany, and is the same as that used today in most countries outside North America.

Flame types are well described and diagrammed. There is an emphasis on using a reducing flame to remove oxides during soldering.

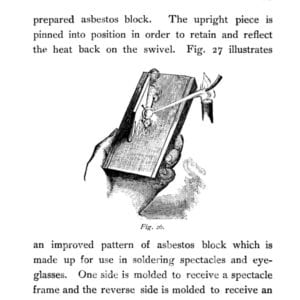

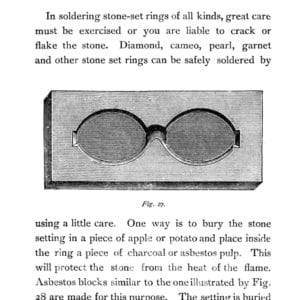

It is claimed that charcoal can embrittle gold alloys heated on it. Asbestos was used a lot and recommended. That would be unthinkable today.

The images of blowpipe soldering different problems let you know how lucky we are to have the torches (and lasers) we do today. The drawings (actually engravings) are very good, thorough and clear.

There are a number of clamping devices for holding pieces for soldering that have been forgotten, and look useful and interesting.

There is a very clear discussion of fluxes, what to use, when appropriate etc. The same with solders, making your own, alloys for solders, constituents and more. The section on alloys has many recipes. Carbon (graphite) ingot molds and crucibles are described and pictured, with automatic systems for melting and tipping. There is a scathing critique of general work quality in soldering and repair. This author would have been in heaven to have had a laser or a fusion welder.

The discussion of repair is excellent, and would benefit anyone today. There is a very interesting section where the author takes you through a number of technical procedures, step by step, with comments. Subtle blowpipe skills are described. What, for people in the West, is interesting, is that if you just go on numbers of people using a technique then this ancient approach is still the most popular in the world, the most used, in Asia, India and other places I suspect there are still more users of this approach than of high tech (and expensive) torches.

I think every jeweler should learn to use a blowpipe. For chain repair a .00 blowpipe can equal a 0 mini-torch. While traveling I once hard soldered a chain using a candle and a Bic pen tube. A useful skill for the extreme jeweler.

There is an excellent section on testing gold alloys for gold content. Using apples and potatoes to protect a gem during ring sizing is described. (I like paper towel and water mush for this myself). Repairs and joint types are covered.

An interesting book, well worth adding to your library.

Charles Lewton-Brain 2013

File Size: 9.70MB, 74 Pages