This 1907 book is 155 pages jammed full of information not found anywhere else in the same way. This third edition seriously updates previous editions of the book as discoveries were being made at the time.

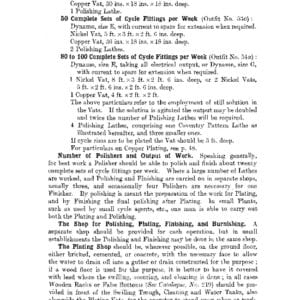

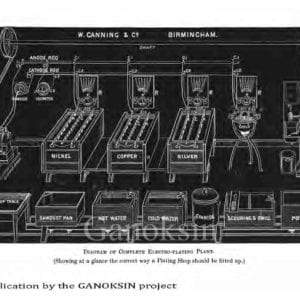

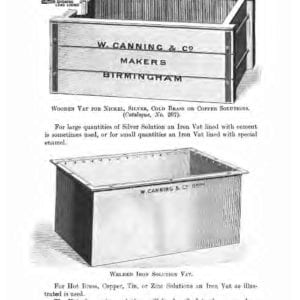

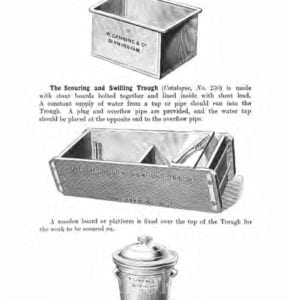

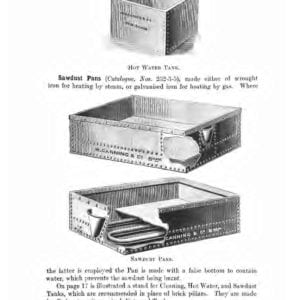

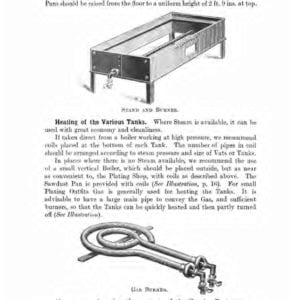

The aim of the book was to provide practical information rather than high theoretical and chemical studies. Nickel plating is extensively addressed as it was then the most common form of plating and was heavily used in bicycle manufacture. The necessity of using pure chemicals is stressed to avoid problems. The book was created to help users get the most out of the chemicals, supplies and equipment that the Canning company sold. This book is a kind of catalog, and manual for use, for the various tools and machines the company producted. Great illustrations and images.

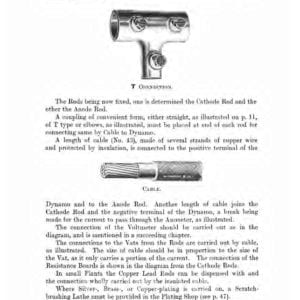

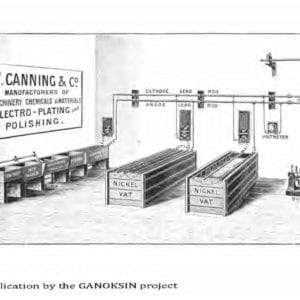

There is an extensive discussion about setting up a plating shop and the considerations for that. Back then a ‘dynamo’ was used to generate power, these days we have nice constant current power supplies which take care of many power issues then extant.

The descriptions of generators, controls, switches etc offer some really Frankenstein-like photographs of control boards and machines. There are excellent principles that are scattered in the text, notes on burning plating, on what you can and can’t do with different solutions and materials. The principles of plating are spelled out, and through repetition – hammered home. Some of the safety information is rather suspect, for instance testing the lye vat for effectiveness by dipping your fingers in it and feeling for the sliminess of dissolving skin cells. Electro-cleaning is well described. Recipes for plating solutions are given and there is a lot of emphasis on cyanide based solutions, activating baths for anodes etc. The use of a “#1 Twaddle hydrometer” is frequent to measure specific gravity (yes that is really its name).

The chapter on silver plating is thorough. There is an interesting technique for locally re-plating worn areas, using calico cloth soaked in plating solution with a silver anode strapped to it to build up the plated metal on a specific spot. Bright silver plating solution recipes are addressed as is recovering silver from used solution. Immersion (dipped) electro-less plating solutions are described.

There is a chapter on gold plating and gilding. Plating the insides of cups, sugar bowls etc is explained. Resist plating (using ‘stopping off’ materials) to get multi-colored plating, such as gold flowers on a silver background, is described.

There is a chapter on tin plating objects which I have not seen described elsewhere. One of the methods is to use cream of tartar along with small tin pieces, heat and then stir your objects in it to plate them with tin.

There is an excellent section on copper electroforming using sulfuric acid based solutions (called electrotyping). This is used for making copies of objects, creating printing plates, molds and more. Iron electroforming on top of copper is addressed.

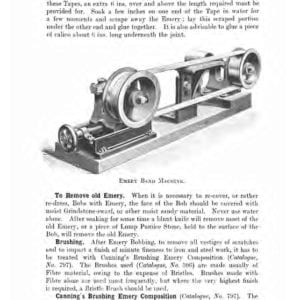

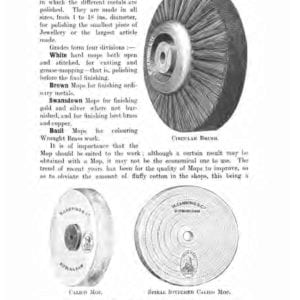

A chapter on scratch brushing and one on burnishing cover information not found elsewhere. A pretty exhaustive chapter on batteries describes how to make them, and maintain them, all different kinds. The chapter on polishing claims to be the one of the few works on polishing written to that date. It describes antique approaches to making buffs which included gluing leather to wooden discs, then coating them with hot glue and rolling the wheels onto abrasives to make cutting and polishing wheels. Early exhaust systems are shown. Buff materials (and abrasives) are dealt with in depth, including felts, bullneck and seahorse leather (walrus). A solid section on tumble burnishing is the earliest thorough discussion of burnish tumbling I have come across.

A number of the chemical mixtures used are proprietary but there is enough recipe information to be of use, especially in the chapter on patination and ‘bronzing’ (what we call patination today). There are many recipes accurately described. The chapter on lacquering is really good, and has hot and cold approaches well described. Low temperature enamelling with baked on enamel paints is addressed as it pertains to bicycles, transfers and enamel logos etc.

An interesting book with many unique illustrations and images. Well worth a read.