Tip for Improving Casting Quality

Every caster has seen his or her fair share of investment inclusions. You'll be polishing a casting when suddenly a whole will pop up with a bit of investment inside. You then have to dig out the investment and fill in the hole with wire, using a laser welder. It's time consuming -- not to mention an inferior product.

1 Minute Read

Every caster has seen his or her fair share of investment inclusions. You'll be polishing a casting when suddenly a whole will pop up with a bit of investment inside. You then have to dig out the investment and fill in the hole with wire, using a laser welder. It's time consuming - not to mention an inferior product.

During some recent experiments that I was conducting on burnouts, I captured an investment inclusion in the making. It occurred when I was cutting platinum flasks down the middle to study various stages of burnout.

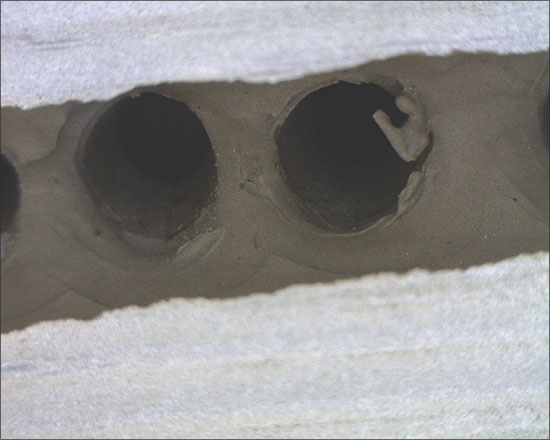

The photo here is a cutaway view of a flask, showing the investment after the wax has been mostly removed with a partial burnout cycle. You can see at the openings - the junctions of the feed sprues and the main sprue - tiny pieces of investment hanging off the sides. When a centrifugal casting machine shoots molten metal into that hole at high velocity, the investment will break off and become a problematic inclusion.

Avoiding the number one cause of this problem is a simple fix: Take care to seal and create a fillet between the feed sprues and the main sprue in your casting tree. Spending a little more time on the front end will avoid nasty surprises on the back end.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.