Methods to Effectively Bend Tubing

Jewelers need to bend tubing for various constructions, including neckpieces, earrings, catches, and cuff links. Normally, precious metal tubes are quite thin (between 0.3 and 0.5 mm) because of material cost. At these thicknesses, tubes are easy to kink or dent, thus ruining the bend and making tight bends problematic.

2 Minute Read

Jewelers need to bend tubing for various constructions, including neckpieces, earrings, catches, and cuff links. Normally, precious metal tubes are quite thin (between 0.3 and 0.5 mm) because of material cost. At these thicknesses, tubes are easy to kink or dent, thus ruining the bend and making tight bends problematic.

Try the following approaches for bending tubing effectively:

Handy Work

Using your fingers and working gently, slowly, and with frequent annealings can work well. (Note: If you carefully heat a tube with a torch while you bend it, it often curves uniformly. No glow should be visible from the metal. I have had surprising success with this approach.)

I have a friend who made lovely cuff links in the form of spiral tubing (think a big spring) using just his hands. He used thin-walled sterling tubing and bent it with his fingers, taking his time to make a perfect, unkinked spiral that measured about ¾ inch in diameter. He then set gems in the ends of the tube.

Bending a long piece of tubing with your hands is much easier than bending a short piece. For example, a piece of tubing that measures about 8 inches long provides so much leverage that when the ends of the tube are held and carefully bent, the center will often bend well and smoothly. However, this involves so much waste that it's not always an option. Instead, you can temporarily solder rods or non-precious tubes to the ends of short pieces of precious tube to bend it, and then remove the extra pieces.

Fill 'Er Up

Filling a tube with support material can help you to bend it effectively. You can pour a low-melting-temperature metal inside the tube before bending it and later melt it out. (I use metals from Small Parts Inc., smallparts.com, which melt in hot water.) You can also try using wax or freezing water inside a tube to make ice, but I find that they do not work as well for support materials as metal.

For larger sizes of tubing, you can roll red European pitch into "snakes" that harden and can be fed into a tube and warmed to fill it. In addition, you can pack the tube with a stiff, fine powder such as sand, sugar, or Plaster of Paris, cork the ends, and bend it.

Get Jiggy

For tubing with a diameter larger than 1/8 inch, you can use small versions of plumbers' tube-bending jigs, but you may notice a bit of flattening in the bent area. You can find these jigs in automotive and hobby stores.

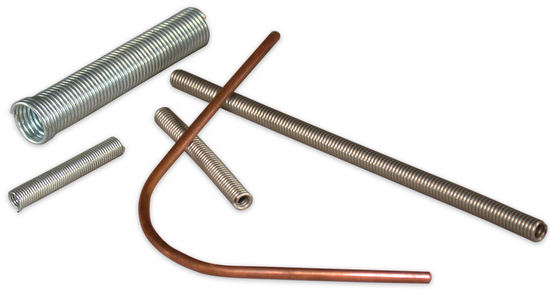

Tightly wound springs work well for any diameter of tube when slipped over it for bending. This method is very effective, particularly if you can get a stiff steel spring into which the tube fits tightly.

Customized Solutions

David Cruickshank of Sydney, Australia, uses a very interesting method for curving tubing to make hollow earrings. He uses a steel rod with a curl on the end and a drawplate to curl tube tightly, making precise jump rings. To see the trick explained step-by-step, http://davidcruickshank.ganoksin.com/blogs/.

The award-winning Journal is published monthly by MJSA, the trade association for professional jewelry makers, designers, and related suppliers. It offers design ideas, fabrication and production techniques, bench tips, business and marketing insights, and trend and technology updates—the information crucial for business success. “More than other publications, MJSA Journal is oriented toward people like me: those trying to earn a living by designing and making jewelry,” says Jim Binnion of James Binnion Metal Arts.

Click here to read our latest articles

Click here to get a FREE four-month trial subscription.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Charles Lewton-Brain

Master goldsmith Charles Lewton-Brain trained, studied and worked in Germany, Canada and the United States to learn the skills he uses. Charles Lewton-Brain is one of the original creators of Ganoksin.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.