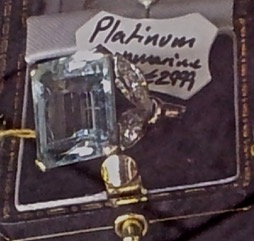

I'm making an engagement ring which is a bit out of my comfort

zone.

I'm having trouble working out how to go about soldering two 6 x 4

mm marquise settings either side of a huge emerald cut aquamarine.

I'm using 18ct yellow gold settings. I wondered about binding wire

but that seemed too clumsy.

This sort of assembly is generally soldered in plaster.

You set up the settings on a soft base. I was taught to use

plasticine, but some people prefer sticky wax.

You arrange the settings into position, being careful to press them

into the base material deeply enough so that the points of contact

where they will be soldered are covered, but leaving the prongs

exposed.

You then make a wall around the set up, so that the assembly is

sitting in a little well. You pour plaster of paris into this well,

covering the assembly, and allow it to harden.

After the plaster has hardened you carefully remove it from the base

and the settings should come away from the support material with the

prongs embedded in the plaster and the girdle and bezel wires

exposed. You’ll be soldering from the back, with the assembled

settings upside-down in the plaster.

You must remove any and all of the base material from between the

settings or it will burn and interfere with the solder. Broken saw

blades are good for prizing the little bits of clay or wax from

between the settings. Also, before the plaster has completely cured

you can trim it with a bench knife so there’s not too much excess

around the set up that might impede the approach of the torch.

Let the plaster dry a good couple of hours before soldering, you

don’t want any residual moisture in the plaster when you heat it.

With the settings firmly set in the plaster you can solder them

together without fear of them moving under the torch. Once all the

joints are soldered and while the plaster is still hot you can quench

it in water and most of the plaster will crumble away.

With gold you are now ready to attach the gallery and shank. If,

however, you use this for a set up in platinum there’s a further

step.

Soldering platinum in plaster makes for very brittle joints. They

will snap easily. With platinum, after soldering you need to set the

clean assembly into a non-reactive high-temperature base and simply

remelt the solder in place. This will remove the brittleness imparted

by the plaster and make the joints strong. In the old days we used

powdered asbestos for this step.

Elliot Nesterman

ajoure.net