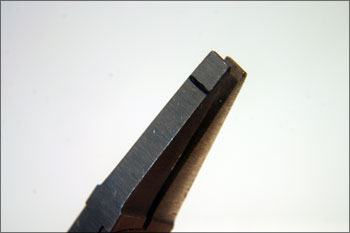

Channel Setting Bezels with Customized Pulling Pliers

These pliers are used to pull back bezels on channel set rings. This allows you to drop in the stones without thinning the edge to allow the stone to drop in. It works especially well with the continuous channel method that the all-set tool creates. Mark the bottom jaws about 0.25 in from the end.

1 Minute Read

This article by Steve Satow shows how to make a customized pulling pliers for channel setting bezels using pulling pliers #111-137.

Customizing your pulling pliers

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

The All-In-One Jewelry Making Solution At Your Fingertips

When you join the Ganoksin community, you get the tools you need to take your work to the next level.

Trusted Jewelry Making Information & Techniques

Sign up to receive the latest articles, techniques, and inspirations with our free newsletter.